The importance of refrigeration in Extra Virgin Olive Oil production

INTARCON2023-06-26T09:40:17+02:00The best Extra Virgin Olive Oil is obtained by cold extraction from olives from early harvests. Olives from the first harvests in October and November offer green and intense oils of superior quality. The importance of refrigeration in the extraction of the oil is explained below.

How is oil extracted from olives?

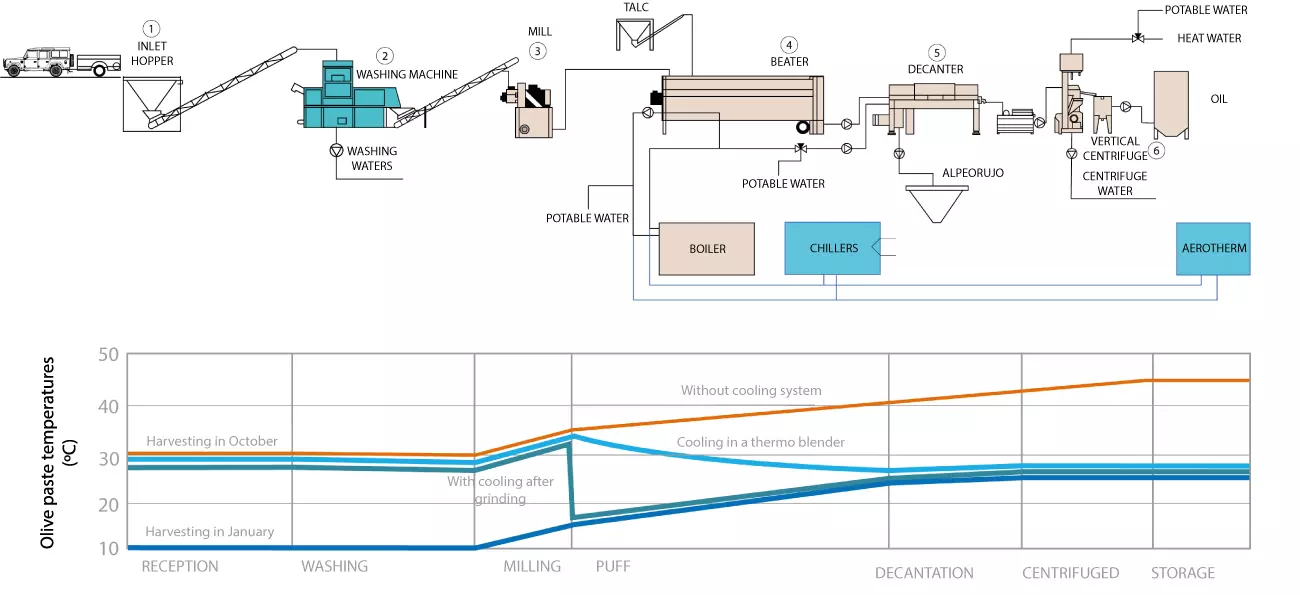

The most common oil extraction process consists of several stages: milling, beating, decanting and centrifugation. Beating is the stage in which, by means of the slow and continuous kneading of the olive paste, at a controlled temperature, the coalescence of the oil droplets is favoured, allowing the subsequent separation of the phases in the centrifugation. The optimum temperature for the production of oils of the highest quality is around 25 ºC, and even below 20 ºC in certain varieties such as Picual or Arbequina.

What is the cold extraction of extra virgin olive oil?

The designation ‘cold extraction’ requires a centrifugation temperature below 27 °C (EC Regulation 1019/2002), while temperatures above 30 °C accelerate the loss of aromas and oxidation and ultimately alter the quality of the oil. Conversely, an excessively low temperature considerably reduces the extraction capacity and hinders the solubilisation of phenols, which give olive oil its characteristic sensory and nutritional properties.

Olive paste cooling system

In recent years, faced with an excess of olive oil production, the sector has put great effort into improving the quality of the oils, with the release of early harvest premium oils. But bringing forward the harvest to the beginning of October has given rise to the problem of “hot pastes”, where the olives can arrive at the mill at around 30 ºC and further increase in temperature during milling and kneading.

As a solution to this problem, the most innovative mills are integrating refrigeration into their process, based on cooling the paste after milling or during mixing.

What systems are available on the market for cooling olive paste?

INTARCON proposes a cooling system for oil extraction based on the cooling and temperature control of the olive paste during the beating process, which is easier to integrate into existing installations, and which provides an optimum and stable temperature throughout the oil production process.

Cooling in the blender is a better solution than cooling after milling. The reason for this is that the transit time of the mass in the blenders is around 90 minutes whereas the transit time in the mill is very fast and intermittent. Cooling after milling would therefore require higher instantaneous power, higher plant power and a larger exchange surface in an additional exchanger inserted after milling. In contrast, the thermo-blenders already have a jacket for temperature control, which would be used in the new cooling system.

The high viscosity of the paste, together with the limited exchange surface of the thermobatteries, makes heat exchange difficult, so the cold supply must be provided at low temperatures by powerful cooling plants that supply glycol below 0 ºC.

The cooling capacity required in the refrigeration chillers is between 5 and 10 kW for each tonne/hour of process capacity. In other words, for an oil mill with a production of around 20 tonnes/hour, a refrigeration plant of between 100 and 200 kW for cooling propylene glycol to -8 ºC would be necessary. The energy cost of the system is less than 0.5 c€ per litre of premium oil, with an investment cost of around 40,000 eur per tonne/hour of capacity.