SMART INVESTMENT

Ammolite chillers have a high return on investment for the refrigeration installation.

High energy efficiency

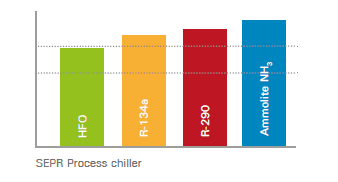

Ammonia has excellent thermodynamic properties, superior to any other refrigerant, with real performance superior to CO2, R134a or R290.

ENVIRONMENTAL SUSTAINABILITY

The most sustainable choice based on current regulations and environmental safety.

Low charge of natural refrigerant

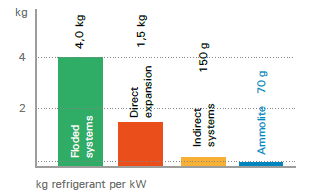

Ammonia has no greenhouse effect and does not damage the ozone layer. Thanks to low refrigerant charge components and a liquid recipient free design, we have achieved the lowest specific refrigerant charge on the ammonia market.

RELIABILITY AND SAFETY

Reliable operation, without safety risks or production losses.

No need for a machine room

A compact system that incorporates an air cooled condenser, dry expansion evaporators and outdoor components, reducing the risk of a possible leak. 2800 hour salt spray test (SWAAT).

Virtual visit

Low charge ammonia technology

Ammolite brings together the latest ammonia technology to reduce the refrigerant charge in the installation. Its system uses the minimum refrigerant load possible, eliminating a refrigerant recipient while using low charge components, such as dry expansion evaporators or microchannel condensers, which reduce the specific charge by 70 g per kW of cooling capacity.

Ammolite chillers have the highest energy efficiency, thanks to the addition of low-consumption components like EC fans, permanent magnet motors and the naturally high efficiency of ammonia refrigerant.

All this allows guarantees the best seasonal energy efficiency ratio (SEER) on the market in accordance with the European Ecodesign Directive.

Ammolite offers low energy consumption and zero greenhouse effect that make it the most sustainable solution on the market.

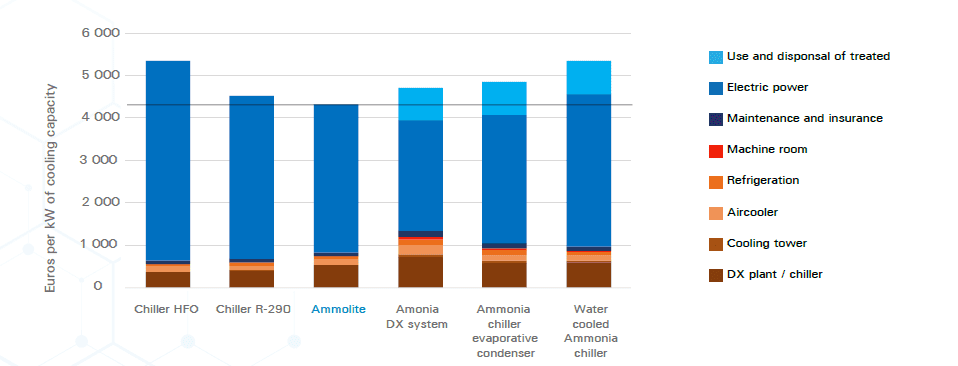

A wise investment

The life cycle cost of a refrigeration system includes the initial investment and operational costs throughout its lifespan. Costs include electrical, evaporative condenser water bills and maintenance.

The best compromise is a contained extra initial investment with a quick return on investment based on future lower operating costs. This cost analysis compares a new system with previous basic reference installation.

Ammolite is the best choice for a the lowest life cycle cost.

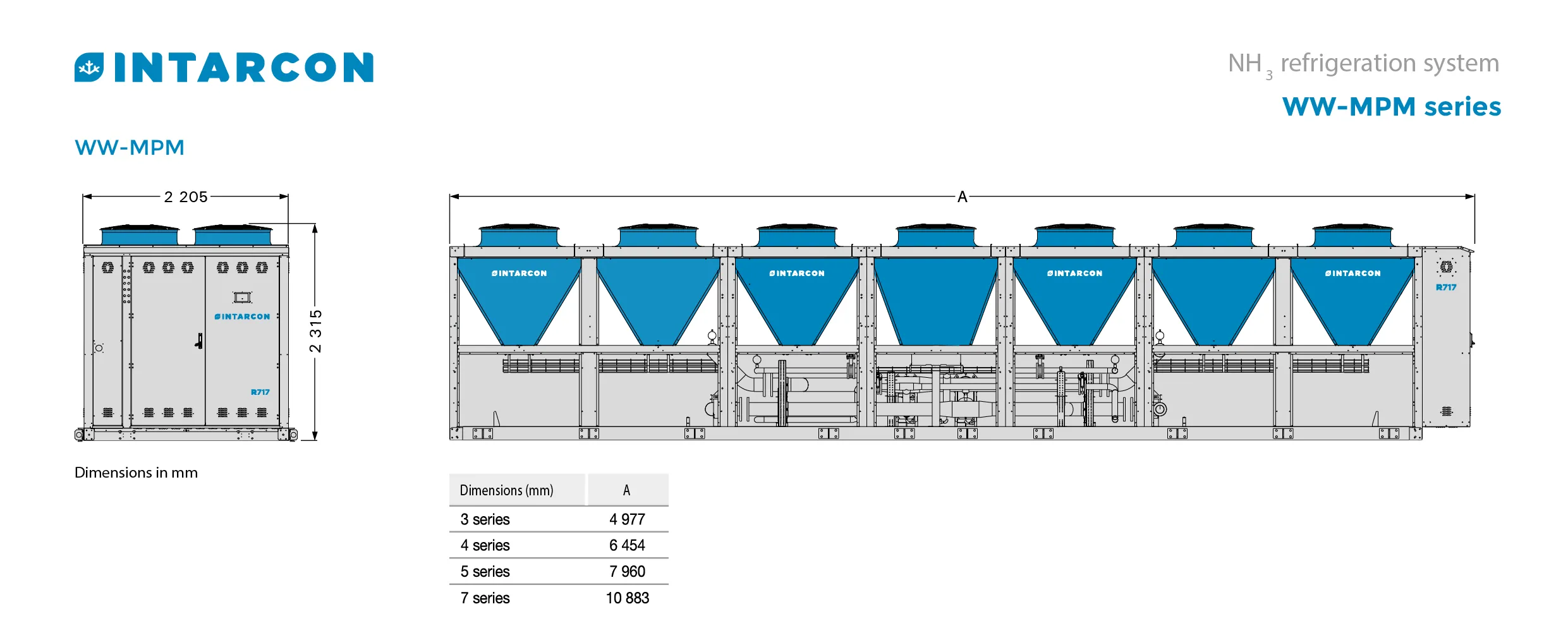

- Industrial refrigeration chiller with low ammonia charge technology developed by INTARCON, for positive and negative temperature air-condensed applications. Compact construction built in galvanised steel body and chassis with polyester paint, for outdoor installation.

- 400V 3N 50Hz power supply. Available in 60 Hz. Other voltages on request.

- Semihermetic screw compressors with variable speed permanent magnet motor. Suction filter, oil filter, discharge check valve. Suction and discharge valves integrated in the compressor.

- Miscible oil.

- High efficiency vertical oil separator.

- Tropicalised condenser with aluminium microchannel coils, with Polyester Powder Coating treatment.

- Oil cooler with stainless steel tube coils and aluminium fins.

- Variable speed EC motor fans for condensing pressure and oil temperature control.

- Evaporator with stainless steel welded plates with stainless steel welding.

- Electronic expansion valve, and electronic liquid injection valve for compressor cooling in extreme conditions.

- Stainless steel refrigeration circuit per compressor with decanter. Filter service valves, sight glasses, pressure switches and high and low pressure transducers.

- Stainless steel hydraulic circuit with fill/drain valve, air vent, flow switch, inlet and outlet thermometers and pressure gauges.

- Closed economiser with plate heat exchanger for liquid subcooling and medium pressure injection (only in negative temperature models).

- Electrical control panel. Frequency variator per compressor. Differential protection. Individual magneto-thermal and thermal protection for compressor and fans.

- Electronic control with digital control panel, cooling capacity control, condensation control, VI variation, start/stop sequence, compressor, fan and pump safety and stop sequence, compressor/s, fans and pumps safeties. Web interface and external communication.

- Multi-tube stainless steel tube evaporator.

- Stainless steel tube condenser and aluminium fins.

- Variable glycol flow rate.

- Condensation heat recovery.

- Total heat recovery (80 %).

- Hydraulic unit with back-up pump.