How to choose a refrigeration unit?

INTARCON2022-06-17T14:17:46+02:00Choose a refrigeration unit is important because refrigeration is present in many processes and applications, not only food products, medicines, chemicals, raw materials, process products…

The correct choice of refrigeration equipment is essential so that the product to be preserved does not lose its properties, the installation is efficient and environmentally sustainable, as well as not entailing a high investment for the end customer.

This choice must take into consideration several criteria: regulations, type of refrigeration system, type of compressor, sizing of equipment and installation and the location of the installation, which will determine the climatic conditions in which the unit will operate. It is also important to know whether the equipment will be installed inside or outside the building.

Important regulations for the installation and choice of refrigeration equipment.

In Europe, the regulatory framework affecting refrigeration equipment is very broad, covering regulations and restrictions on equipment design, safety regulations, sales and handling of fluorinated gases, gas quota agreement, safety and environmental requirements, etc.

Within these regulations we find the F-Gas, a regulation applicable in the European Union that establishes, among other things, a timetable for the reduction and gradual prohibition of fluorinated greenhouse gases. It also limits the use of certain refrigerants depending on the application, depending on where the equipment is to be installed.

It is important to be informed about the regulations, as for example the choice of a direct expansion unit for use in supermarkets would be limited to 40 kW.

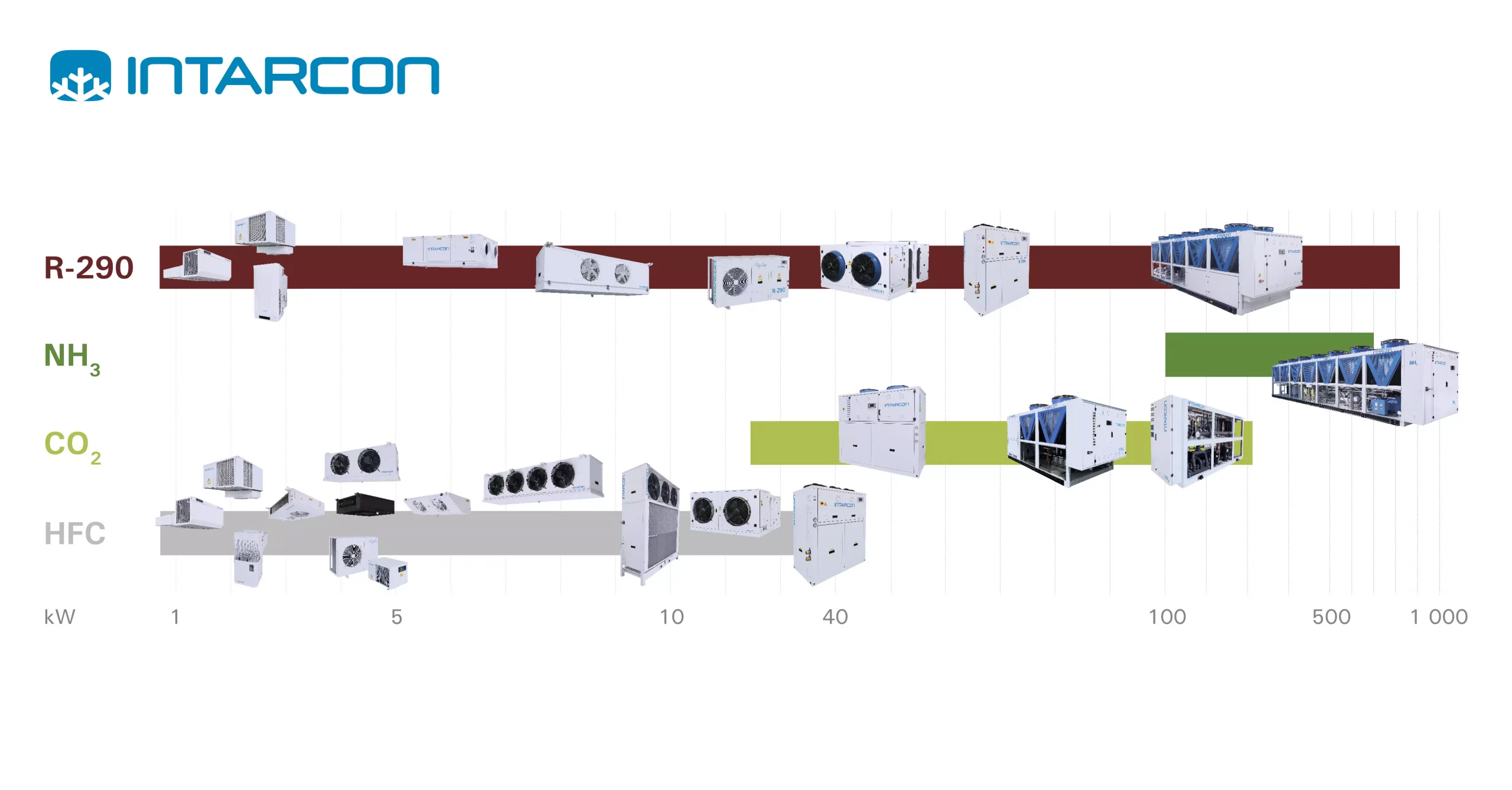

Type of refrigerant in the refrigeration equipment.

The right choice of refrigerant gas for your refrigeration equipment, as well as the regulations, is very important. When choosing the refrigerant to use, several factors must be considered:

- Price of refrigerant.

- GWP (Global-Warming Potential).

- F-Gas Regulation.

- Efficiency and limits of application.

Type of refrigeration system.

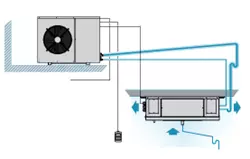

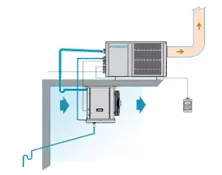

According to the type of refrigeration system, we can classify them as direct and indirect systems.

- Direct refrigeration system: compressed and condensed refrigerant gas leaves the equipment and is distributed to the remote units (evaporators).

- Indirect refrigeration system: the refrigerant gas is confined in the cooling generation zone, where the cooling power is transferred to an intermediate fluid by means of an exchanger. The intermediate fluid (water, glycol or brine), driven by a pumping system, transports it to the final elements such as air coolers, exchangers, tank coils, etc.

Compressor type.

Another factor on how to choose a refrigeration unit can be its main component, the compressor. Let us now look at the most common types of compressors in refrigeration.

According to its structure.

- Hermetic compressors: completely closed, and cannot be opened for maintenance, must be replaced in case of breakdown.

- Semi-hermetic compressors: in the event of a breakdown, they can be demounted for maintenance or replacement of broken components.

According to their compression technology

- Scroll compressors: Compress the refrigerant fluid by means of two rotors in the form of a spiral (or snail). One of these rotors is fixed and the other is movable. In its rotational movement, it compresses the fluid towards the centre of the spirals where it is progressively reduced until it is discharged.

- Reciprocating or piston compressors: These are the most used compressors on the market. They are characterised by a spark plug system that drives compression pistons, similar to internal combustion engines.

- Screw compressors: The refrigerant is compressed by two rotors in the form of a screw without an end tip, which are perfectly adapted to each other. The refrigerant is fed through threads along the shaft, increases in pressure and is discharged when it reaches the end of the two rotors.

Location of installation.

For the design and optimal operation of a refrigeration system, the temperature difference is a very important factor, as it determines the heat exchange in the evaporator and condenser. Also the humidity in coastal areas.

Camera size.

The size of the chamber is important when choosing equipment, as we may be short of power to cool the product in good conditions. Or on the other hand, we may choose an oversized unit, so we will be paying for more power, which we do not need.

Equipment configuration.

Refrigeration equipment can be axial or centrifugal in configuration.

- Axial refrigeration equipment: equipment for installation outside the building.

- Centrifugal refrigeration equipment: the condensing unit is installed inside the building. These units incorporate a centrifugal turbine that allows the hot air to be conducted to the outside through air ducts.

Installation of a split refrigeration unit in axial version.

Intallation of a split refrigeration unit in centrifugal version.

How not to make a mistake when you choose a refrigeration unit?

INTARCON has the system Calcooling, a software developed to calculate the refrigeration needs of a cold room and select the refrigeration equipment, where by introducing certain parameters according to the type of cold room (modular, refrigerated cabinet, display cabinet, building site…), type of insulation and size, the refrigeration calculator indicates the appropriate equipment..

In addition to indicating the type of cold room, the refrigeration calculator knows the standard conservation parameters for all types of products (meat, vegetables, cereals, dairy products, fruit, pharmaceutical products, bread, wine, seafood…), and allows you to enter the number of door openings, daily air renewals, external humidity or even the product load in the cold room. With all this data, the tool gives us the refrigeration needs of that chamber, in other words, the refrigeration power you need to conserve the product optimally.

With these technical requirements, and taking into account the regulations for the installation of refrigeration equipment, we can choose the ideal equipment for the cold room.