How to choose the right refrigerant gas for your equipment

INTARCON2022-07-12T13:25:04+02:00The aim of this article is to analyse the different factors that must be taken into account when choosing the type of refrigerant gas for commercial refrigeration equipment considering the chamber temperature range in which we want to operate.

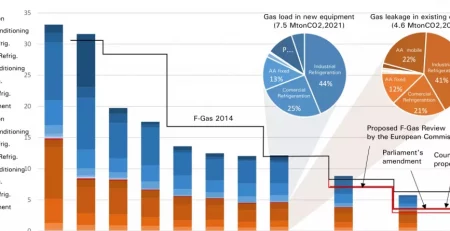

Traditionally in recent decades, the refrigerant par excellence used in commercial refrigeration has been R404A, which has characteristics that make it ideal for low, medium and even high temperatures. Following the entry into force of the F-Gas Directive in Spain and with the threat of the imminent prohibition in 2020 of the refrigerant R404A by European regulation F-Gas, the different manufacturers and distributors of gases have launched various refrigerant gases on the market as direct substitutes for R404A.

Factors to consider when choosing a refrigerant gas:

- Price of the refrigerant in question. In the case of R404A, the price has increased 7-fold over the course of 2017, currently exceeding €120/kg.

- GWP (Global-Warming Potential). It is interesting that this index is as low as possible, since the Spanish legislation in force contemplates a tax applicable to all gases with GWP > 150. In case the gas has a GWP > 150, it will pay a tax that is directly proportional to the GWP of the gas in question (tax = 0.015 x GWP), which can reach very high values (for the case of R404A: 0.015 x 3921.6 = 58.82 €/kg).

- European F-Gas Regulation on the prohibition of fluorinated gases. It establishes a phase-down calendar and a gradual prohibition of the current refrigerant gases. There are a range of alternative HFC blends to R404A on the market, such as R407A, R407F, R442, etc. The only virtue of these refrigerant cocktails is that they have a GWP of around 2000 compared to 3921 for R404A, however they all have a dangerously high discharge temperature which compromises their use in low temperature applications without proper precautions.

- Efficiency and application limits: We must choose an efficient refrigerant whose evaporation pressure under working conditions is higher than atmospheric pressure (thus preventing the circuit from working in a vacuum) and is within the operating limits of the compressor. On the other hand, the saturation pressure in condensing conditions must have a moderate value that is within the limits of the compressor, not exceeding the maximum admissible pressure of the refrigerant circuit or its components.

Gases suitable for commercial refrigeration

Based on the above and after studying the wide range of refrigerants available on the market, we can highlight the following gases as the most suitable for commercial refrigeration:

- R452A.Direct substitute for R404A, but with a moderate GWP = 2139 and a high market price. Applicable in low, medium and high temperature.

- R449A. It has similar properties and is an almost direct substitute for R404A with a GWP one third lower than R404A (GWP = 1396), but its high discharge temperature when operating at low temperatures should be noted, which in most cases requires the installation of a liquid injection system to cool the gas.

- R290 (propano CH3CH2CH3). High-performance natural refrigerant with a low and stable price, no risk of obsolescence, very low global warming power (GWP = 3), and therefore tax-free. It is an excellent refrigerant for both low and medium temperatures. The only inconvenience is that it is classified according to RSIF as safety class A3 (high flammability), so certain precautions must be taken in design and manipulation.

- R134a.Refrigerant with very good characteristics for working at medium and high temperatures, with GWP = 1300, with no expiry date yet for the use of this refrigerant in commercial refrigeration.

- R513A.Direct substitute for R134a, but with a moderate GWP = 629 and a high market price. Applicable in medium and high temperature.

Recommendations for choosing refrigerant gas according to equipment

- Low temperature: Chamber temperature between -25 and -15 °C.

- Small compact units: By far the most suitable refrigerant is R290.

- Other compact and semi-compact equipment: R452A or R449A can be chosen, although we consider the latter to be more interesting due to its lower GWP.

- Medium temperature: Chamber temperature between -5 and +10 °C.

- Small power compact units. Although we could choose R134a, the most suitable refrigerant is R290.

- Other compact and semi-compact equipment. We can choose R452A, R449A, R134a or R513A, although we consider that the two most interesting are R449A and R134a.

- High temperature: Chamber temperature between +9 and +18 °C. In comparison to the above, the refrigerants with the best characteristics for high temperature operation are R134a and R513A, as they can operate at condensing temperatures of over 70 °C.