Wines

Refrigeration units for cellars conditions

Wine cellar refrigeration split systems with low-noise axial or centrifugal condensing unit and double-flow low-profile evaporating unit.

- Description

- Technical features

- Optional

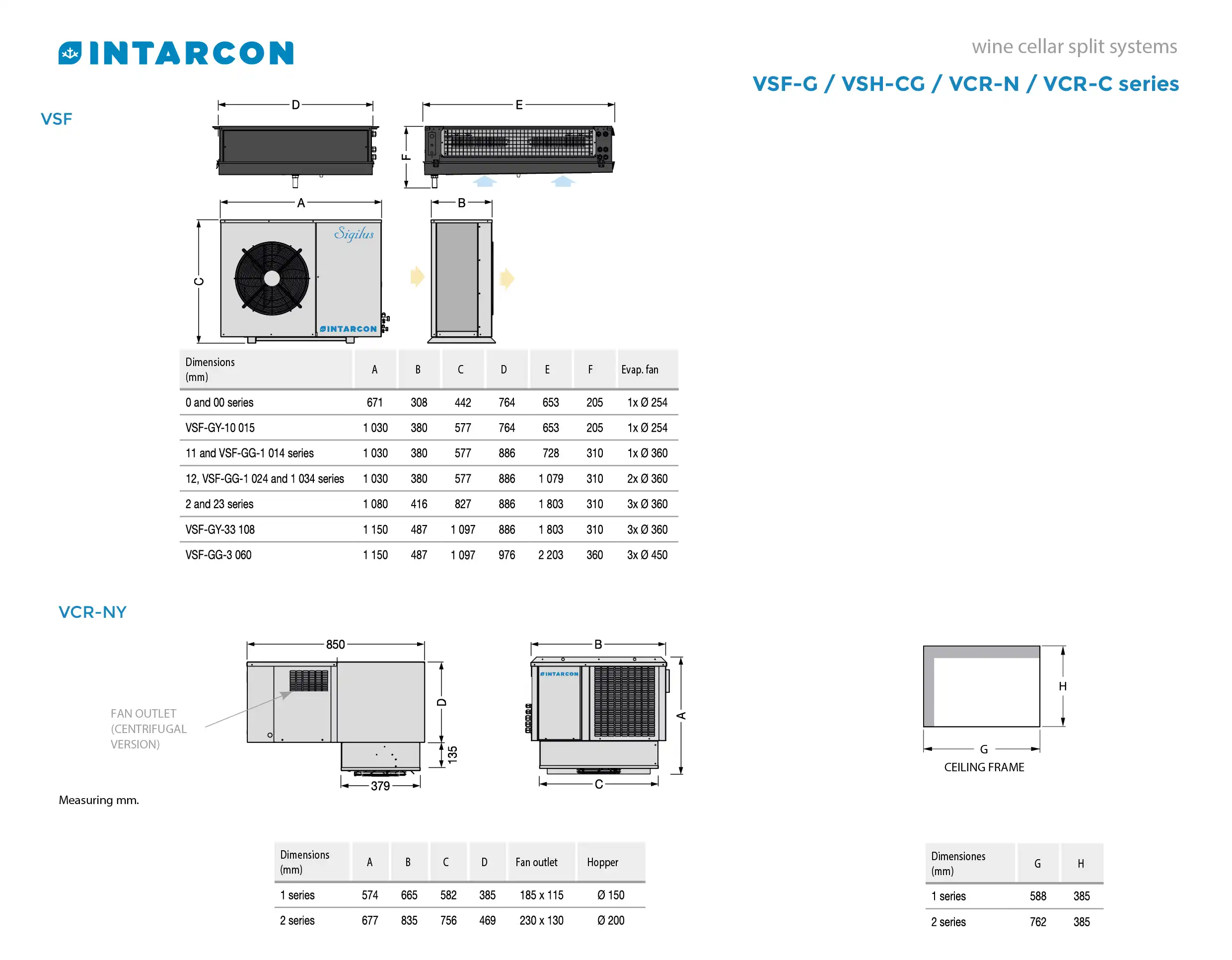

- Dimensions

- Documentation

Description

Wines cellar refrigeration split systems with low-noise axial or centrifugal condensing unit and double-flow evaporating unit with heating function, humidification / dehumidification system and condensed water pump, and compact ceiling construction with axial or centrifugal condensation.

- VSF-G: Wine cellar split systems with low-noise condensing unit.

- VSH-CG: Wine cellar split systems with centrifugal condensing unit.

- VCR-N: Wine cellar roof-top monoblock with axial fan.

- VCR-C: Wine cellar roof-top monoblock with centrifugal fan.

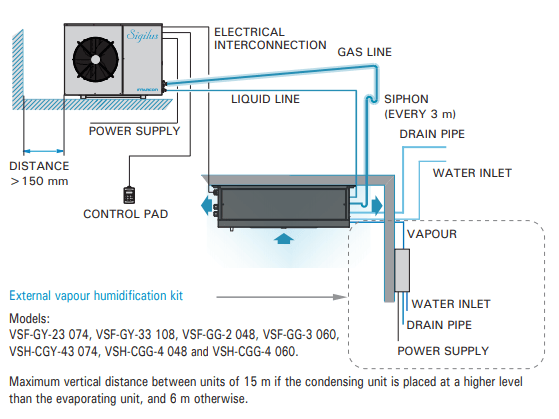

Serie VSH/VSF

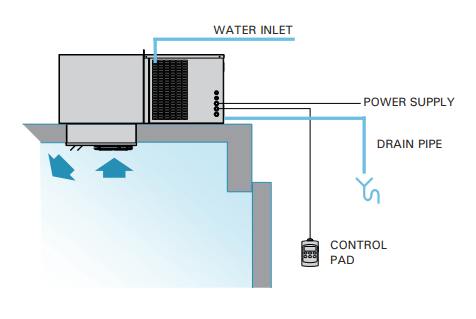

Serie VCR

Conservation of bottled wine

Bottled wine requires temperature and humidity controlled conditions that optimally conserve the product while avoiding both cork drying and label mouldiness.

The wine treatment unit guarantees optimal conditions for the preservation of bottled wine.

Wine conservation in barrel

In the conservation of wine in barrels, the relative humidity inside the cellar is of great importance, which must be adjusted so that there is no transfer of water vapour between the environment of the cellar and the interior of the barrel, avoiding thus wine wastage or water absorption by the content.

External vapour humidification kit

Vapour humidification with 3 kg/h capacity, consisting of: vapour lances integrated in the evaporator unit, a submerged electrode generating cylinder with feed valves and water purge valves.

VSF/VSH

- 230 V-I-50 Hz or 400 V-III-50 Hz power supply. Available in 60 Hz. Other voltages by request.

- Minimal R-134a or R-449A refrigerant load.

- Hermetic reciprocating compressor.

- Double-flow low-profile evaporating unit with heaters and active humidification / dehumidification system; and evaporation anti-corrosion coated coil.

- Air defrost; air filter.

- Built-in solenoid and thermostatic expansion valves.

- Drain pan and condensed water pump.

- Flare-type cooling connections (up to 1/2”-3/4) and service valves.

- Liquid receiver and refrigerant preload for 10 m piping.

- Proportional condensation control (VSF 1/2/3 and VSH 4/43 series) and all / nothing condensation control (VSF 0, VSH 2/22 and 3/33 series).

- Multifunction electronic dual control of temperature and humidity with remote keyboard and digital regulation of condensing temperature.

- MCB protection.

VCR

- R-134a refrigerant load, below 1.5 kg.

- Hermetic reciprocating compressor.

- High and low pressure switches.

- Air defrost.

- Heating elements, humidification / dehumidification system.

- Evaporation coils with anti-corrosion coating.

- Water purge system.

- Thermostatic expansion valve.

- Evaporation drawer of 50 mm sandwich panel made of polyurethane foam, internally coated with pre-lacquered steel plate.

- Multifunction electronic dual control of temperature and humidity with remote keyboard and digital regulation of condensing temperature.

VSF/VSH series

- Change to 400 V-III-50 Hz power supply.

- Proportional control of condensing pressure through fan speed variation (already included in VSF 1/2/3 and VSH 4/43 series).

- Built-in oil separator.

- Condenser coil polyurethane anti-corrosion treatment.

- Coil protection grille.

VCR serie

- Non-return discharge damper (VCR-C series).

- Adaptation of air discharge to circular duct.

- Vertical air flow (centrifugal version).