Sigilus

Glycol chiller

Coolers in compact and silent construction for glycol.

- Description

- Technical features

- Options

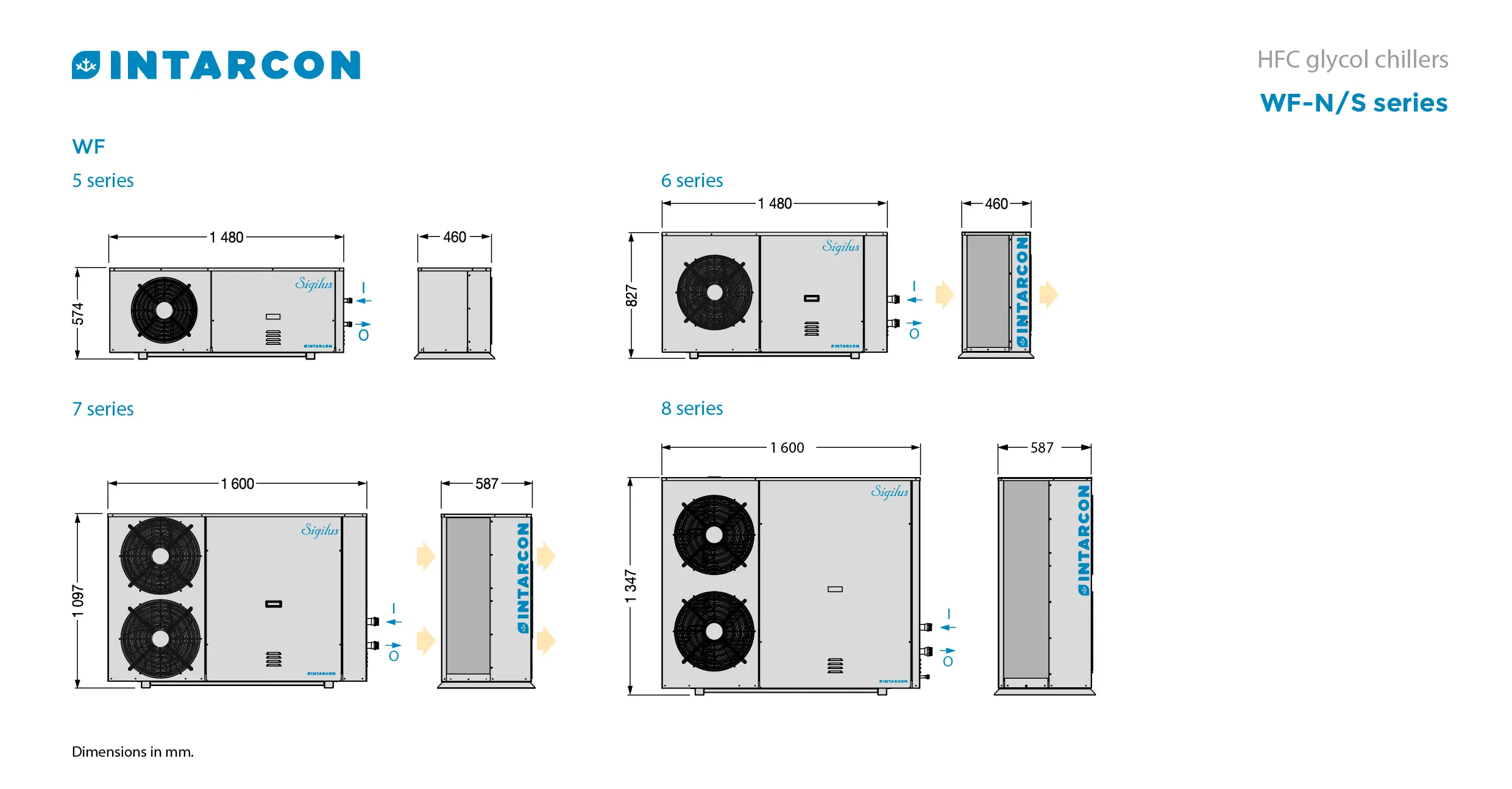

- Dimensions

- Documentation

Description

Air-cooled, water or glycol condensing chillers, with silent operation and compact construction in galvanised steel bodywork and structure in polyester paint for outdoor installation.

- Operation with water or glycol.

- Minimum coolant charge.

- Integrated hydraulic circuit.

- 230V 50Hz or 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Hermetic reciprocating or scroll compressor, acoustically insulated, with discharge silencer (in hermetic reciprocating compressor), mounted on dampers, with internal clixon and crankcase heater.

- Large-surface condensing coil made of copper tubes and aluminium fins, with tropicalised dimensioning for ambient temperatures up to 50 °C.

- Low-speed, nozzle-mounted motor fans, dynamically balanced propellers and external protection grilles.

- Proportional condensing pressure control by means of fan speed variation (optional on single-phase models).

- Cooling circuit equipped with high and low pressure switches, ceramic filter and sight glass.

- Stainless steel plate heat exchanger.

- Electric power and control panel, with differential and magneto-thermal protection for compressor, fan/s and hydraulic pump.

- Hydraulic circuit made of copper pipe with threaded connections, fill/drain valve, air vent, flow switch, thermometers and inlet/outlet pressure gauges. Threaded connections.

- Liquid injection in low temperature models with R-449A.

- Built-in hydraulic unit with glycol circulating pump, expansion vessel, safety valve, mesh filter, air vent and filling valve (positive temperature models).

- Proportional condensing control (standard on three-phase models).

- Coil anti-corrosion coating.

- External coil protection grille.

Control panel

- 230V 50Hz or 400V 3N 50Hz power supply.

- Main switch.

- Multifunction electronic controller, with the following functions:

- Compressor, fans and circulator pump management.

- Proportional control of condensing pressure by varying fan speed (three-phase models).

- Glycol inlet/outlet probes and evaporating temperature probe.

- Safety control and operation alarms.

- RS485 connection with MODBUS RTU communication protocol.