R290 intarWatt

R290 chillers

Chillers in compact construction and outdoor installation of glycol, water or brine and a low R290 charge.

- Description

- Technical features

- Options

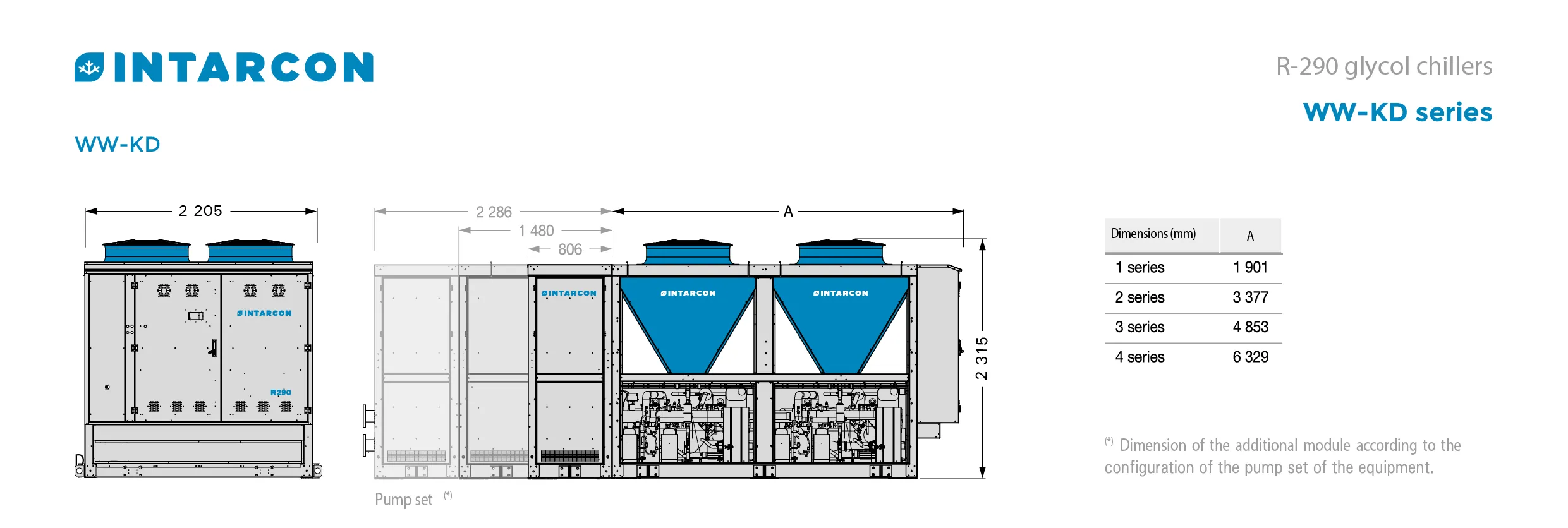

- Dimensions

- Documentation

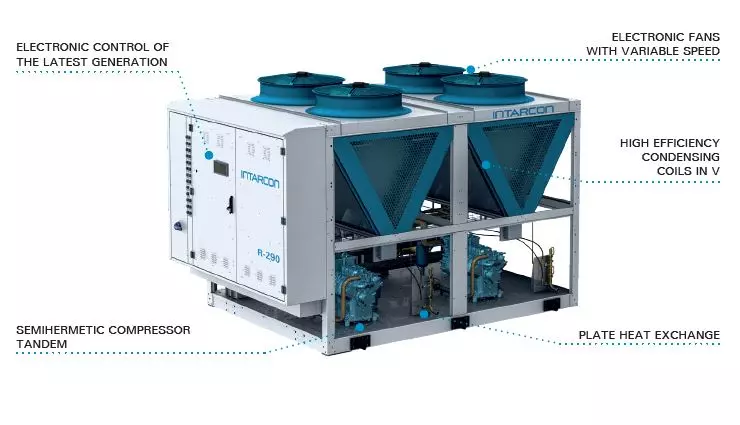

Description

Water, glycol or brine chiller for outdoor industrial refrigeration applications. Also, the R290 intarWatt chiller is characterised by:

- Built-in hydraulic unit (optional).

- Low refrigerant charge R-290.

- No need for machine room.

- Plug & Play system.

- Optimised compact system, with minimum maintenance.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Reduce refrigerant charge of R-290.

- Manufactured with galvanised steel casing and polyester paint.

- Semihermetic compressor tandem for R-290 with capacity control and unloaded start, crankcase heater.

- Oil separator and oil balancing line.

- Micro-tube V condensing coil with aluminium fins and 7 mm copper pipes.

- Two electronic fans per V with variable speed.

- Plate heat exchanger with electronic expansion valve per circuit.

- Heat exchanger for liquid subcooling and suction superheating.

- Cooling circuit made of annealed copper or steel tube with soldered connections, filter drier, ATEX high and low pressure switches, pressure transducers and temperature probes.

- Hydraulic circuit made of copper pipe with threaded or flanged connections, fill/drain valve, air vent, flow switch, thermometers and inlet/outlet pressure gauges.

- External IP55 electrical panel with extraction fan. Individual protection of compressors and fans.

- Progamable Emerson control, with variable refrigeration control (digital compressor only), condensing pressure control with floating set point, and variable glycol flow

control.

- Hydraulic group.

- Variable flow pump to control glycol flow.

- Anti-corrosion treatment based on polyurethane coating for the condensing coil.

- Electronic control and spare driver.

- Silentblocks for equipment installation.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.

- Independent compressor compartment with leak detector and ATEX extraction fans.