Heat on demand – Full INVERTER

R290 chillers

Glycol, water or brine chiller plants with reduced R290 load and Full INVERTER compressors.

- Description

- Technical features

- Options

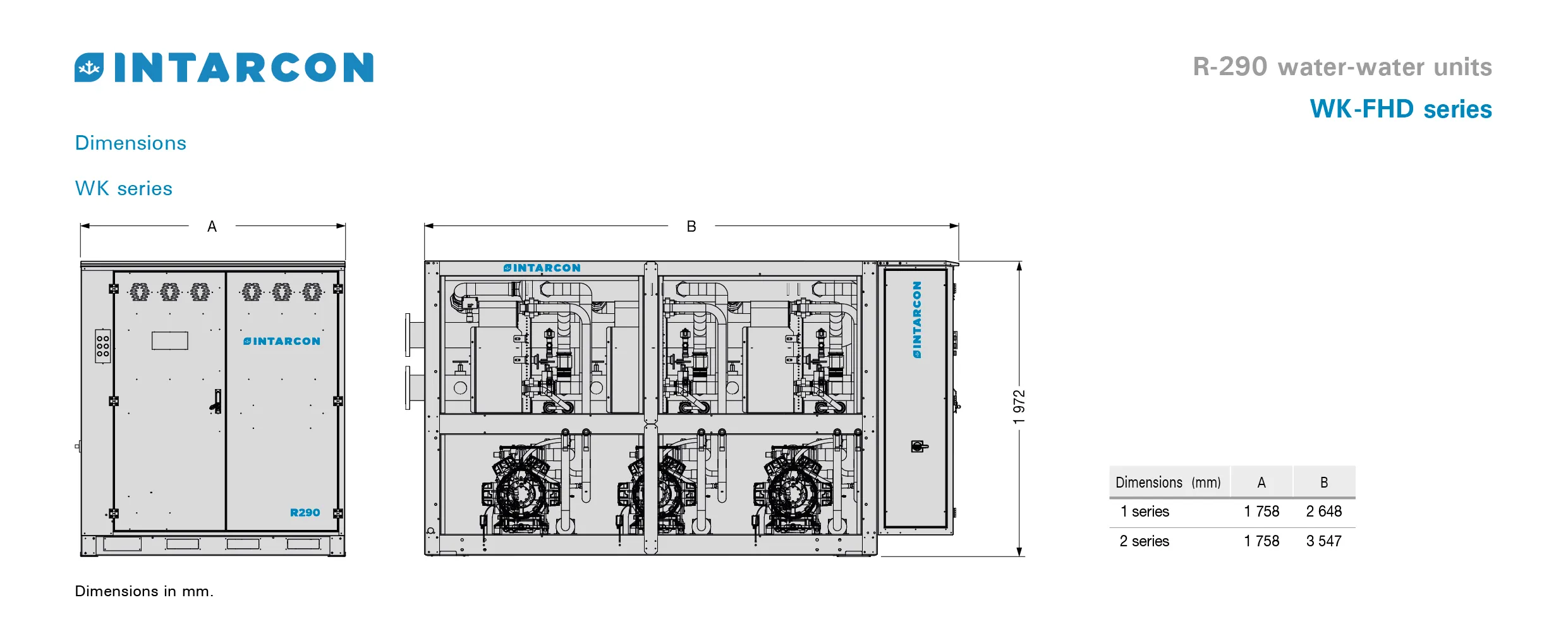

- Dimensions

- Documentation

Description

Water or glycol chiller plants for commercial and industrial refrigeration applications with reduced R-290 load and Full INVERTER compressors.

- Natural refrigerant R-290.

- High energy efficiency.

- Reduced plant occupation.

- Full INVERTER compressors

- Compatible with hydraulic units in evaporator and condenser.

What is the Full INVERTER system?

The Full INVERTER system provides precise control over the glycol supply temperature, in the face of a variable refrigeration demand. This system controls sequentially and simultaneously the capacity of the compressors, varying the motor speed from 30 to 70Hz, and avoiding starts and stops, with significant energy savings.

- 380÷460 V 3 ~ 50/60 Hz power supply. Others voltages by request.

- R-290 low refrigerant charge.

- Self-supporting body made of galvanised steel sheet with polyester paint for outdoor use.

- Semi-hermetic compressors with unloaded start with Inverter drive in each compressor, assembled on silentblocks, with rotalock service valves, ATEX class crankcase heater and electronic protection module.

- Refrigeration circuit made of annealed copper tube with soldered joints, filter drier, high and low pressure switches, pressure transducers, temperature probes and ducted safety valves.

- Pure copper brazed stainless steel plate evaporators and condensers.

- Liquid solenoid valves and electronic expansion valves.

- Cold water hydraulic circuit made of stainless steel (≥DN100) or annealed copper tube (<DN100), with fill/drain valve, air bleeder, electronic flow switch, inlet and outlet thermometers and pressure gauges.

- Hot water hydraulic circuit made of stainless steel (≥DN100) or annealed copper tube (<DN100), with fill/drain valve, air bleeder, electronic flow switch, inlet and outlet thermomanometers.

- Watertight control and power control panel with independent differential and magnetothermal protection per compressor. Forced ventilation in electrical panel.

- Programmable electronic control board with temperature control over the unit cold water circuit, remote control of the primary pumps for cold and hot water circuits, remote start-stop, remote setpoint control via 0-10V signal and alarm indicator light.

- Hot water inlet temperature between +10 °C and +50 °C.

- Change to Bitzer Full INVERTER compressor, except 75HP models (on request)

- Leak detector.

- Paneling prepared for outdoors with acoustic panelling, ATEX extraction fan and differential air pressure switch.

- Rodent-proof paneling prepared for outdoors.

- Electronic control and spare driver.

- Compressor network analyser.

- Network analyser in general supply.

- Network analyser in general supply with current consumption prevention. Multi-tube heat exchanger in evaporator and condenser.

- Silentblock.

- Heat mode setting, which allows it to work according to the setpoint temperature of the hot water circuit.