High humidity

Refrigeration split units

Split high temperature refrigeration units and pasive relative humidity control.

- Description

- Technical features

- Optional

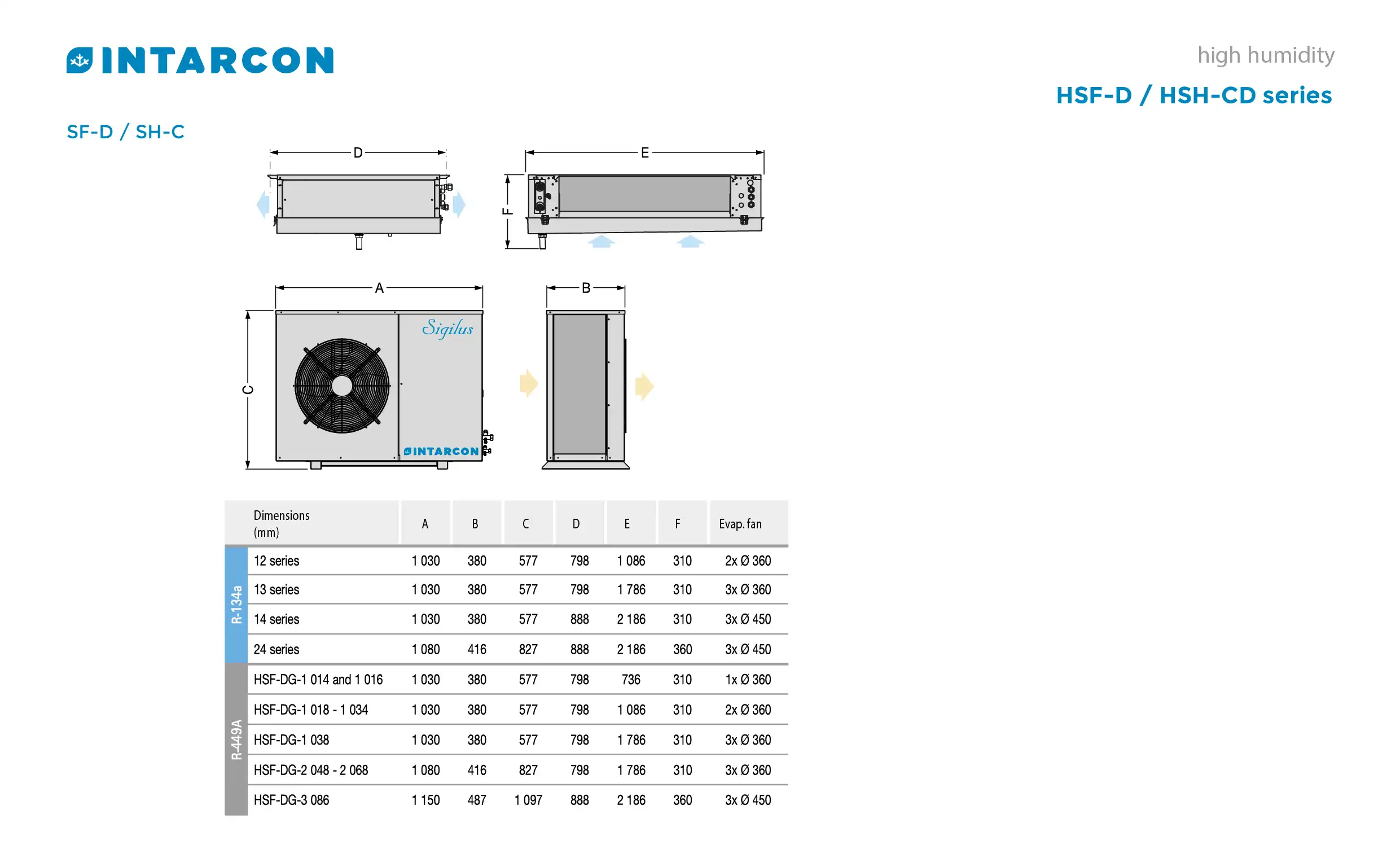

- Dimensions

- Documentation

Description

High humidity is a split refrigeration system for high relative humidity applications in a positive temperature range, featuring an evaporating unit with double air flow, and a low-noise or centrifugal condensing unit.

High Humidity systems are available in two configurations:

- HSF-D: Split systems with low-noise condensing unit and high humidity double-flow evaporating unit.

- HSH-CD: Split systems with centrifugal condensing unit and high humidity double-flow evaporating unit.

Conservation at controlled relative humidity

The preservation of certain products, such as fruits, vegetables or cut flowers, requires control of the relative humidity in the cold room within a certain range.

These unit adjusted for high relative humidity are especially suitable for fruit and vegetable products preservation cold room.

The evaporators have a double air discharge through oversized coils to obtain up to a high level of relative humidity inside the chamber at around 95 %, avoiding loss of humidity and weight of the product.

Electronic temperature and humidity control

The unit incorporates an advanced electronic regulation for the control of the temperature and humidity inside the cold room.

- Multifunction remote digital control with temperature and relative humidity display.

- Relative humidity control in the regulation range from 60 % to 95 %*.

- Optionally, active humidification kits with steam lances and dehumidification and stove kits are integrated.

* The humidity regulation in the cold room is carried out passively, acting on the evaporator flow, without water vapour. The actual range of humidity regulation depends largely on the conditions of the cold room, absolute outside humidity and type of product.

- 230 V-I-50 Hz or 400 V-III-50 Hz power supply. Avaible in 60 Hz. Others voltages by request.

- Minimal R-134a or R-449A refrigerant load.

- Hermetic reciprocating compressor.

- High and low pressure switches.

- Oversized double air flow evaporating unit designed for relative humidity control between 60 % and 95 %*.

- Built-in solenoid and thermostatic expansion valves (evaporating unit).

- Air defrost.

- Drain pan.

- Flare-type connections (up to 1/2”-3/4”) with service valves.

- MCB protection.

- Liquid receiver.

- Refrigerant preload for 10 m piping.

- Multifunction electronic control with temperature and humidity control and remote keyboard.

- Change to 400 V-III-50 Hz power supply.

- Proportional control of condensing pressure through fan speed variation (already included in 2/22 series and above).

- Coil protection grille.

- Built-in active humidification kit.

- Dehumidification and heating kit.

- Built-in oil separator.

- Anti-corrosion evaporator coil coating.

- Anti-corrosion condenser coil coating.