intarsplit axial

Refrigeration split units

Refrigeration axial split units for cold rooms.

- Description

- Technical features

- Optional

- Dimensions

- Documentation

Description

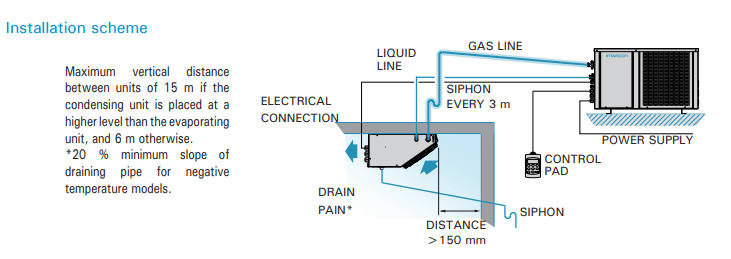

Intarsplit axial is a split system for small and medium size cold rooms at positive and negative temperature, composed by a condensing unit in horizontal construction and a slim-type, cubic-type or double-flow evaporating unit.

Intarsplit series combines the last refrigeration technology with traditional tested solutions in a very compact design. They have a strong structure but featuring also a reduced weight, and minimum refrigerant load. They are built in galvanized steel with polyester paint.

They include a complete electronic regulation with remote controller and digital condensation control.

Intarsplit units are available in different configurations:

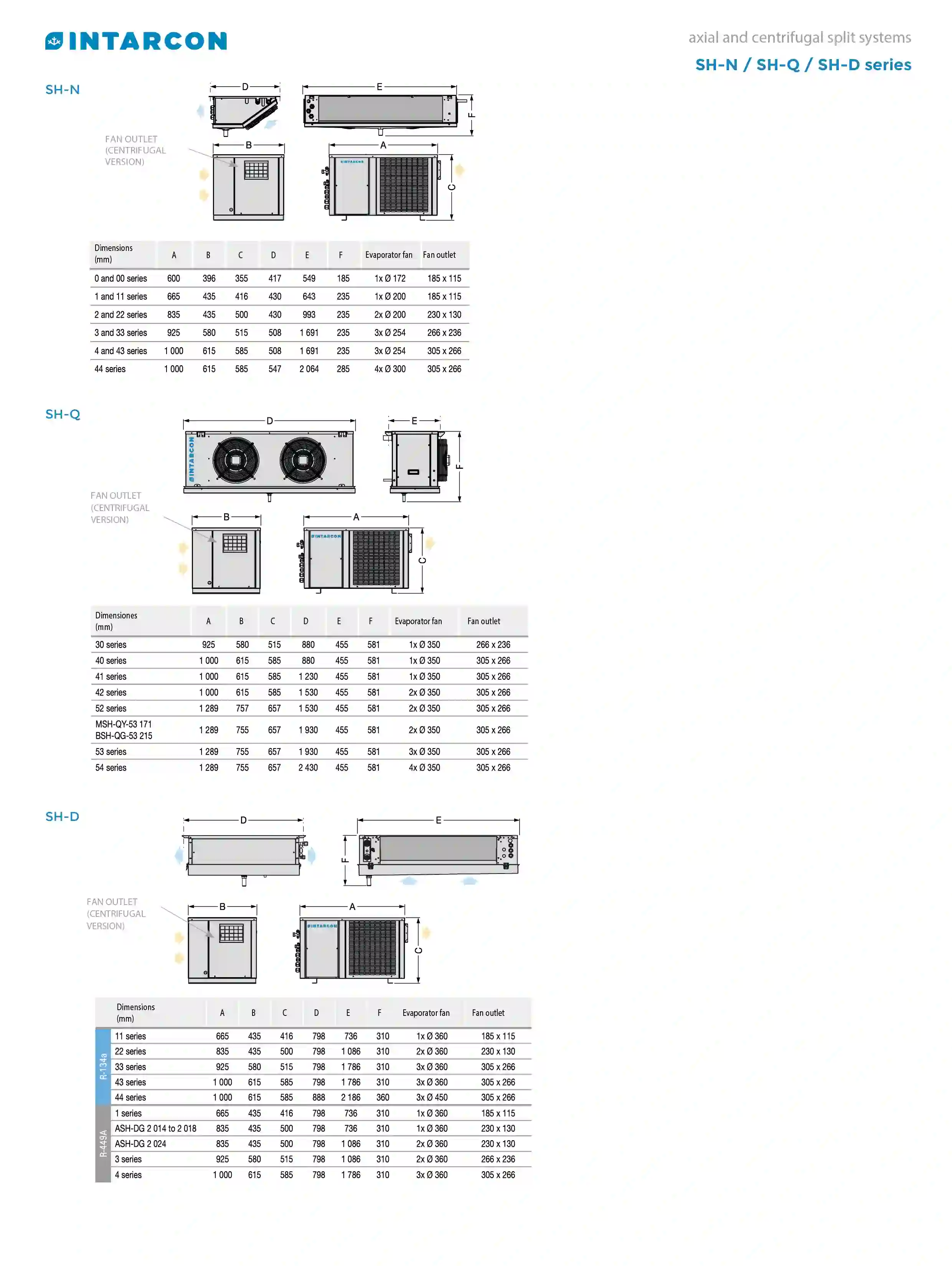

- SH-N: Split systems with axial condensing unit and slim-type evaporating unit.

- SH-Q: Split systems with axial condensing unit and cubic-type evaporating unit.

- SH-D: Split systems with axial condensing unit and double-flow evaporating unit.

- 230 V-I-50 Hz or 400 V-III-50 Hz power supply. Available in 60 Hz. Others voltages by request.

- Minimal R-134a or R-449A refrigerant load.

- Hermetic reciprocating compressor (noise insulation in 3-phases models).

- High and low pressure switches.

- Liquid receiver.

- Refrigerant preload for 10 m of piping.

- Thermostatic expansion valve.

- Electrical heater defrost (except ASH series).

- Drain pan.

- Flare-type connections (up to 3/8”-3/4”) and service valves.

- 10 m of electrical connections included (except for 4 series and 40 up to 54).

- MCB protection.

- Multifunction electronic control with remote keyboard and digital regulation of condensing pressure.

- Liquid injection system for negative temperature models with R-449A

MSH-N / BSH-N

- Change to 400 V-III-50 Hz power supply.

- Crankcase heater.

- Proportional control of condensing pressure: 3/33 and 4/43/44 series

- Rectangular to circular exhaust air adaptor.

- Built-in oil separator.

- Anti-corrosion evaporator coil coating.

- Anti-corrosion condenser coil coating.

- Larger sized multifunction electronic control.

MSH-Q / BSH-Q

- Change to 400 V-III-50 Hz power supply.

- Crankcase heater.

- Proportional control of condensing pressure.

- Rectangular to circular exhaust air adaptor.

- Built-in oil separator.

- Anti-corrosion evaporator coil coating.

- Anti-corrosion condenser coil coating.

- Larger sized multifunction electronic control.

ASH-D

- Change to 400 V-III-50 Hz power supply.

- Crankcase heater.

- Proportional control of condensing pressure: 3/33 and 4/43/44 series

- Rectangular to circular exhaust air adaptor.

- Built-in oil separator.

- Anti-corrosion evaporator coil coating.

- Anti-corrosion condenser coil coating.

- Condensed water pump.

- Larger sized multifunction electronic control.