Refrigeration in ham dryers

Ham dryers are rooms in which the maturation and drying phase takes place in a controlled environment. The optimal conditions in these facilities cause the ham to cure slowly, acquiring organoleptic properties suitable for human consumption, such as flavour, texture, hardness, etc.

This process is one of the most important during the production of the product. However, the ideal climatic conditions for this in a natural way are not found everywhere, which is why it is necessary to create these drying sheds.

What should we know about the curing process in ham dryers?

Before carrying out this process, it is essential to understand the chemical composition of the product prior to drying and to know certain key aspects that will guarantee a high quality result at the end of the curing process in ham drying sheds.

The chemical composition of ham before curing varies according to several factors, such as the breed of pig, its feed, the age at the time of slaughter and the preparation process. However, in general, we could say that it includes the following main components:

- Water: Fresh ham contains a high percentage of water, which can vary considerably between 50% and 70% of its total weight.

- Proteins: They are responsible for its texture and flavour, making up around 15% to 25% of the total weight of the ham.

- Fats: The amount can vary between 15% and 35% of the total weight of the ham.

- Minerals: It has a variety of minerals that are important for health, such as iron, phosphorus, potassium…

- Carbohydrates: They are the source of energy for the muscle before the animal is slaughtered and represent 1% of its total weight.

- Vitamins: Although in relatively small quantities, fresh ham contains a multitude of vitamins.

Phases of the ham curing process.

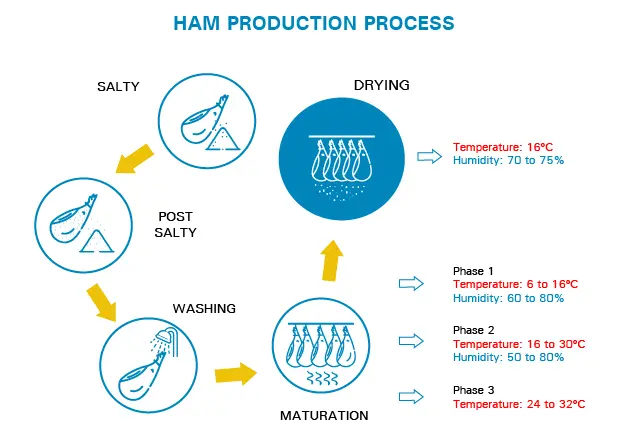

Now that we already know the product, we must know the phases or processes that the product has to undergo until the final result is obtained:

- Salting: is the process by which salt is uniformly applied to the surface of the meat and its cuts. This may vary according to the type of ham and certain factors in which the aim is to extract excess moisture.

- Post-salting: during this process the ham is placed in a resting chamber, where the salt is allowed to distribute evenly throughout the meat where it begins to penetrate the muscle tissue and modify its texture and flavour.

- Washing: the ham is washed and dried to remove excess salt and prepare it for the next stage, where a layer of lard or fat is commonly applied around it to protect the surface of the ham for further processing.

- Maturation: the ham is placed in a drying or maturation cellar or chamber specifically designed to achieve a high quality end result. In this drying or maturation chamber, known as ‘secaderos’, the temperature and humidity are carefully controlled, as well as air circulation, allowing the flavours to develop and intensify throughout the process over time. The duration of this process can vary depending on the quality of the product to be obtained and the type of ham, from months to years.

Phases in the maturation of hams:

-

- First phase: in this first phase, the hams are kept in a room with a controlled environment at a temperature of between 6 and 16ºC and a humidity of between 60% and 80%. In this way we will achieve the dehydration of the ham, reducing the amount of water and melting the fats.

- Second phase: during this phase, the hams are subjected to a progressive increase in temperature between 16 and 30ºC, which causes a decrease in humidity from 50% to 80%.

- Third phase: finally, in this phase, the ham is aged or “estufaje”, where the smell and flavour of the ham is obtained, thanks to a progressive increase in the temperature from 24 to 32ºC.

- Drying: refrigeration plays a fundamental role in the process of drying and preservation of the product in chambers. It is important to maintain the temperature at 16ºC and a relative humidity between 70% and 75%.

Finally, quality controls are carried out throughout the ham curing process to ensure that a quality product is obtained.

Refrigeration in ham dryers

Refrigeration in ham dryers can play an important role in the process of preserving and controlling the quality of certain food products, such as hams and sausages, once they have completed their drying and curing process.

Key aspects of refrigeration in dryers and cellars:

- Long-term storage. After the hams have reached the desired level of curing during the drying process, they can be moved to refrigerated storage cellars. These cellars are designed to keep the hams in low temperature and controlled relative humidity conditions. This helps to prolong their shelf life without negatively affecting the quality of the product.

- Temperature and humidity control. In cold stores, temperatures are generally kept below 15°C to slow down chemical and enzymatic reactions in the ham, which reduces the loss of quality during storage. Relative humidity is also controlled to prevent excessive drying out.

- Prevent the growth of microorganisms. Refrigeration at lower temperatures inhibits the growth of bacteria and micro-organisms, which is important to maintain food safety and prevent spoilage of the product. However, it should be noted that the curing process has already significantly reduced microbial activity in the ham.

- Quality preservation. Refrigeration in storage cellars helps to preserve the quality of cured ham for longer periods. This allows producers and distributors to maintain inventories and plan product distribution over time.

- Controlled conditions. Refrigerated storage warehouses usually have temperature and humidity control systems that ensure a stable and uniform environment. This is essential to avoid fluctuations that may affect product quality.

Refrigeration at this later stage helps to maintain and prolong the quality of the finished product until it is ready for consumption or distribution.

What are the main factors affecting ham dryers?

Ham drying sheds are facilities specifically designed to carry out the drying and maturing process of hams in a controlled manner. These drying sheds must provide an optimal environment for the hams to develop their characteristic flavours and textures.

- Altitude and climate of the location of the dryer, as it must be adapted according to the climatic conditions.

- Size and weight can affect the length of the process required to complete drying.

- Rotation and handling within the dryer may be necessary to ensure uniform ripening, thus avoiding moisture accumulation in the contact areas.

- The design and technology used in the dryer, including the ability to control temperature, humidity and air circulation, are key factors.

- The temperature should be constant and kept between 10 °C and 25 °C. Otherwise, the temperature may influence the acceleration of the process.

- The relative humidity is responsible for controlling the loss of water from the hams, maintaining a range of 60% to 80%. This prevents the formation of a hard outer rind and allows for uniform curing.

- Air circulation is responsible for maintaining a homogeneous environment in terms of temperature and humidity, promoting uniform ripening.

- Drying time will vary depending on the type of ham or the results expected from the product.

- The size and density of the load can hinder air circulation and negatively affect the final quality.

- Hygiene and cleanliness of the dryer.

- Supervision and control.

What do we offer?

Depending on the size of the project, INTARCON offers a range of cooling solutions for dryers to control the temperature of any product. In addition, we offer a wide range of alternatives with different gases and a specially developed product range in our product portfolio.

In addition to the quality and easy installation of the equipment, INTARCON stands out for its ability to advise and design cooling projects adapted to the needs of each client.

We have a large commercial and prescription team with extensive experience and training for the execution of projects aimed at this sector. Our objective is to offer the best solution, analysing all the alternatives and proposing the most efficient, reliable and sustainable solution to the client.