Cold rooms for the preservation and maturation of meat in the HORECA sector

INTARCON2024-12-11T13:56:16+01:00En este post hablaremos sobre la importancia de las cámaras frigoríficas para conservación y maduración de carne en el sector HORECA.

La carne es un producto perecedero natural, dejarlo expuesto al calor, la luz, las vibraciones o fluctuaciones en la temperatura y la humedad, puede hacer que cualquier tipo de carne se deteriore. Cuando se almacena adecuadamente, la carne no sólo mantiene su calidad, sino que para las piezas más exquisitas pueden mejorarse considerablemente en ternura, textura y sabor.

¿Qué es “rigor mortis”?

El “rigor mortis” o “rigidez de la muerte” es un cambio químico en los músculos de un animal que suele aparecer a las 3-4 horas después de la muerte y que suele tener un efecto completo a las 12 horas aproximadamente. Cuando ocurre el rigor mortis, es síntoma de que la glucosa ha dejado de llegar a los músculos, generándose ácido láctico que cubre esa falta de glucosa, y apareciendo la rigidez en los mismos.

Una vez que el ácido láctico ha invadido el cuerpo y transcurridos unos días, comienza a eliminarse con lentitud. Los músculos se relajan y los tejidos comienzan a ceder, obteniendo un producto para un consumo óptimo.

Si consumiéramos la carne justo después de ser sacrificado el animal, esta será gomosa y dura en mayor o menor medida dependiendo del estrés que haya sufrido el animal al ser abatido. En cambio, si la carne se consume tras un proceso óptimo de maduración, esta será mucho más tierna y sabrosa. Por este motivo, lo habitual es que en la industria cárnica se dejen reposar las carnes al menos 10 días antes de comercializarlas.

¿Qué es la maduración de carne?

El proceso de maduración de carne busca obtener una carne más sabrosa y blanda antes de ser consumida, y básicamente consiste en dejarla reposar el tiempo que sea necesario para darle así descanso a los músculos que se encuentran rígidos (rigor mortis) hasta que desaparezca dicha rigidez, consiguiendo a su vez un envejecimiento de esta.

¿Cómo se realiza la maduración de carne?

Existen fundamentalmente dos tipos de procesos de maduración de carne:

Maduración en húmedo o al vacío

Este proceso consiste en, transcurridas al menos 48 horas del sacrificio del animal, envasar al vacío las piezas de carne, extrayendo todo el aire que las rodea para minimizar el crecimiento de bacterias aerobias y ralentizar así el proceso de degradación de origen bacteriano.

Temperatura y condiciones de conservación de la maduración en húmedo o al vacío

Podemos de este modo, además de conservar, madurar carnes minimizando las mermas de peso siempre y cuando garantizamos que la temperatura se mantiene rigurosamente entre 1,5 y 3 °C, no siendo necesario para este caso controlar la humedad.

En este tipo de maduración, no se precisa que las piezas de carne tengan la grasa uniformemente distribuida, y el espacio de almacenamiento necesario es mucho menor que en otros procesos de maduración.

Las piezas refrigeradas se suelen dejar madurar habitualmente entre 7 y 14 días, con un máximo de 20 a 25 días, ya que a partir de ahí la carne puede tomar olores y sabores no deseados.

Maduración en seco

En este tipo de maduración de carne se seleccionan piezas de gran calidad con un alto contenido en grasa que debe estar distribuida de manera uniforme, la cual protegerá a las piezas de un deterioro interno. La carne se hace reposar en un ambiente de temperatura y humedad controladas durante un largo periodo de tiempo para su envejecimiento. Se obtiene de este modo una carne de calidad excepcional, con un gran sabor según los expertos.

Del mismo modo, es importante mantener una baja velocidad de circulación de aire en la cámara. Esto se consigue con evaporadores de doble flujo de aire que incorporan ventiladores ajustados a una mínima velocidad de giro para simular la circulación de aire por convección natural al igual que un evaporador estático.

Temperatura y condiciones de conservación de la maduración en seco

La clave de los equipos de maduración de carne en seco está en el control de la humedad. Se recomienda que exista una alta humedad relativa, ya que mantiene el producto húmedo y la evaporación al mínimo. Los equipos de refrigeración para la maduración de carne están configurados para cámaras en el entorno de los 0 °C y la humedad relativa en el rango del 65 % al 85 %. Asimismo, hay que tener en cuenta que humedades excesivamente bajas puede secar el producto.

El tiempo mínimo recomendado este tipo de proceso de maduración dependerá del sexo y edad del animal en cuestión, pero en todo caso es largo.

Se consigue con este proceso de maduración en seco que, por un lado, la acción de las enzimas endógenas presentes de forma natural en la carne desintegren los tejidos conjuntivos del músculo, produciendo el ablandamiento de la carne. Por otro lado, la pérdida de humedad que se traducirá en una elevada concentración del sabor de esta, muy superior al de la carne fresca envasada al vacío, además de una textura mucho más suave.

Ventajas

Este tipo de maduración favorece la proliferación de moho (hongos) en la superficie de la carne, no suponiendo esto ninguna merma de calidad, incluso ayudan a ablandar y potenciar el sabor de esta. Simplemente hay que tener la precaución de cortar y desechar esa costra antes de cocinar.

Visto lo anterior, podemos deducir que la carne madurada en seco es un producto destinado fundamentalmente a establecimientos de restauración donde se valore la calidad dejando el aspecto económico en segundo plano, pues es evidente que el valor de una pieza de carne madurada en seco tendrá un precio mucho más elevado que una pieza sin madurar. Este incremento se justifica primero por la merma de peso que sufrirá la carne, segundo por la complejidad del proceso de maduración en sí mismo (control preciso de temperatura y humedad), y tercero por el tiempo que las piezas de carne deben estar madurando.

Se conoce como cava o armario de maduración de carne aquella que habitualmente se integra en la sala de un restaurante para mejorar la calidad del producto cárnico permitiendo a los comensales ver y escoger la pieza que más les guste.

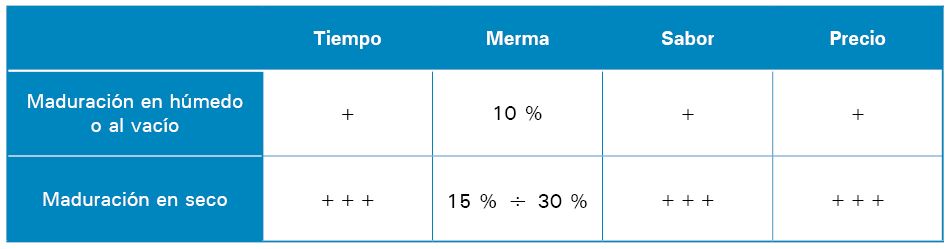

Maduración al vacío vs. maduración en seco

Analizando esta comparativa podemos ver que los dos métodos son perfectamente válidos y de hecho ambos se usan en la actualidad habitualmente, aunque cada uno de ellos estará enfocado a un mercado y a un cliente diferente. Vemos que los procesos de maduración al vacío son rápidos y eficientes, y por tanto son adecuados cuando lo que se valora es la rapidez y el precio. Por otro lado, la maduración en seco nos ofrece un notable plus de calidad, pero lógicamente a un precio más elevado.

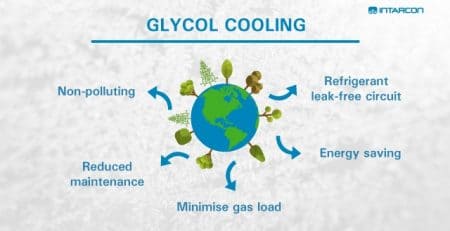

Una vez conocidas las condiciones de conservación, veamos los equipos INTARCON disponibles especialmente diseñados para estas aplicaciones, que garantizan las condiciones óptimas de conservación y maduración de carne:

Gama de equipos INTARCON para maduración de carne en seco

Los equipos para maduración de carne están disponibles en construcción semicompacta silenciosa o centrífuga.

Las principales características son las siguientes:

- Evaporador quasiestático de doble flujo a muy baja velocidad, especialmente diseñado para conservación de carne

- Control activo de humedad relativa de la cámara, incorporando humidificador a vapor de 3 kg/h de capacidad, con lanzas de vapor integradas en la unidad evaporadora

- Regulación electrónica con mando a distancia y control de condensación digital

- Precarga de gas refrigerante incluida

Gracias a los equipos para maduración de carne, se pueden mantener en sus condiciones óptimas en una temperatura de 0 °C, y una humedad relativa del 65-85 %.

Supervisión y control de la instalación

Dada la importancia de mantener la cadena de frío en la conservación y maduración de carne, la instalación de los equipos de refrigeración puede ir equipada con el novedoso sistema kiconex, el cual dota a los equipos e instalaciones de hiperconectividad a internet con almacenamiento de datos y computación en la nube.

A través de su plataforma tanto el instalador como el propietario de la instalación pueden acceder de manera remota a la supervisión y control de la instalación, contando con gráficas de datos a tiempo real, y permitiendo modificar si se desease los parámetros de refrigeración de la instalación.