Refrigeration history

INTARCON2023-05-25T10:46:51+02:00Before going into the history of refrigeration, we will explain very briefly the why of refrigeration. We will first talk about Know-Why and then move on to concepts that could be defined as Know-How.

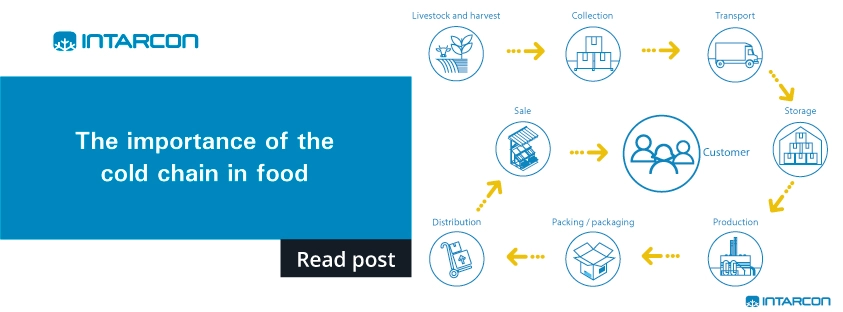

The importance of refrigeration in food preservation

The need for refrigeration in food preservation has to do with two basic concepts:

- Bacterial activity develops between approximately 5 °C and 65 °C, depending mainly on the type of bacteria and ambient humidity. The listeria bacterium is unfortunately still active even at values close to 0 °C.

- The other element of micro-organism development depends on the fraction of free water present in the medium.

From this it is clear that any means used to reduce temperatures to levels, say below 4 °C, slows down the proliferation of these harmful elements.

What is the reduction of the free water fraction?

Drying and salting, for example, have historically represented the solution to preserve food by reducing the amount of water contained in the food. These processes result in the reduction of the free fraction of water.

In the extreme northern regions, indigenous populations discovered that the rapid freezing of meat and fish, exposed to ambient temperatures of -20ºC, considerably improved the quality of the products to be consumed because freezing transforms a high portion of the water contained in the food into ice, thus ensuring a reduced water content in the liquid or free state.

Do you know about the vitreous point?

A further step towards excellence in preservation is the achievement of a temperature approaching the so-called glassy point. At this point, at very low temperatures and depending on the food, between -40 ºC (ice cream) and -80 ºC (fish and meat) the presence of free water is practically nil and a powerful bactericidal and virucidal effect is obtained. At these temperatures, almost all enzyme activity is also disrupted.

This is the reason for creating freezing and preservation systems for bluefin tuna, and other prized species, that allow temperatures of -60 ºC to be reached. This ensures that all organoleptic and colour qualities are maintained at the same level as freshly caught fish.

History of refrigeration

Today, refrigeration is synonymous with freezers and refrigerators in our homes. But the use of refrigeration dates back to the time of the Egyptians, Greeks and Romans who began to use natural caves to store and preserve snow and ice in the warm or hot periods of the year in order to preserve food. In this way, it allowed kings and nobles to enjoy cold food and drink in their castles and mansions.

There are many sources that describe how these snow pits were built, in shady and cool places, using straw and sawdust for their preservation. The stored snow was pressed to compact it and allow it to be preserved for a longer period of time.

In those times, this activity generated work and some wealth among the chain of people who carried out this activity. From the “boleros” who collected the snow, the “guardas” who guarded the wells and the “arrieros” who transported the snow during the coldest hours to reduce its thawing as much as possible.

Throughout the history of refrigeration, techniques were also developed to allow surface freezing of water contained in special earthenware vessels. The sheets of ice that formed on the surface were added to the ice already stored in neighbouring wells.

How did the refrigeration of the medium get started?

The refrigeration of a medium can be achieved by various methods:

Chemical and Physical

In the first case we are talking about endothermic reactions where the combination of two or more chemical compounds to react absorbs external energy, lowering the temperature. For example, mixtures of water with sodium and potassium nitrate or another very interesting mixture of ice and salt.

For example, the American Nancy Johnson invented the first hand-cranked ice-cream maker in 1843. It was a cylindrical wooden basket containing a metal pot inside. In the space formed between the wooden basket and the pot, a mixture of ice and sodium chloride was placed, which had the function of cooling the walls of the pot to temperatures of -16 ºC and thus obtaining an excellent ice cream.

But the first applications were earlier and date back to the 16th century. Blas Villafranca, a Spanish doctor based in Rome, was already cooling drinks using refrigerant mixtures.

The scientific development of this technique in the 17th century is due to Robert Boyle and the astronomer Philippe Laire. In 1715, Daniel Fahrenheit fixed the thermometer using a mixture of snow and ammonium nitrate. Later, in 1760, a scientist by the name of Von Braun succeeded in freezing mercury to -40 ºC.

Physical processes

In these processes, the latent heat of vaporisation is used to, to use a colloquial term, “generate cold”.

The physician and chemist William Cullen is cited as having succeeded in 1748 in producing ice by vaporising ethyl ether into the atmosphere. Due to the high explosive properties of this compound, there were numerous accidents due to the vapours released.

Michael Faraday experimented with the liquefaction and evaporation of other gases including the widely used carbon dioxide (R744).

Subsequently, other refrigerants were used, such as:

- Propane, known today as R290

- Butane (R600a), which is now widely used in domestic refrigerators.

- Ammonia or R717.

As a comment, these processes involved the loss of the generated vapour to the atmosphere during cooling.

How did the first refrigeration systems appear?

Again a doctor, John Gorrie, with the aim of cooling the rooms of patients affected by yellow fever. In 1842 he devised and built the first closed-cycle system. This system was based on the mechanical re-compression of evaporated refrigerant gases and in 1851 he obtained a patent for an ice-making machine.

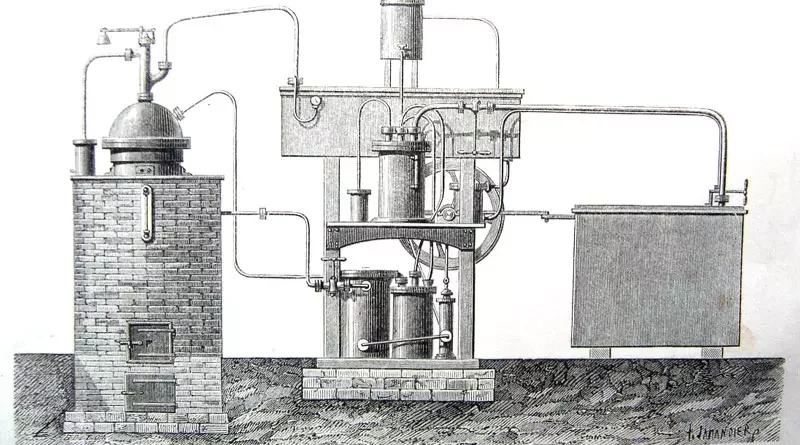

In all closed-cycle refrigeration systems using refrigerants, the aim is to realise a pressure drop that allows the expansion of the liquid refrigerant. It should be explained that this vacuum can be obtained either in the suction phase of a cycle with a mechanical compressor or by absorbing a vapour by means of an absorbent substance. The first ice production systems were developed using an absorption machine developed by Ferdinand Carré in the mid-19th century. These latter systems were conceptually simpler and did not require electrical energy to operate, with steam supplying the energy needed to regenerate the absorbing fluid (water) and release the refrigerant fluid (ammonia).

This system continued, with variants and improvements, until 1950, when, due to its lower efficiency compared to mechanical compression, it was discontinued.

However, due to the possibility of using alternative energy such as waste heat or solar energy, they were reintroduced with different systems such as water or lithium bromide in positive temperature systems. In this way, the first systems in the history of refrigeration were established.

As far as mechanical compression systems are concerned, Jacob Perkins patented the first ice machine in 1834. This is a refrigeration system based on compression, expansion, evaporation and condensation, using ethyl ether as the refrigerant gas. But the wide availability of cheap natural ice from the USA meant that the project was not commercially successful.

On this basis, the French engineer Charles Tellier, building on previous work, devised the first industrial refrigeration machine using methyl ether. Initially intended to produce ice, the invention was immediately used to build refrigeration systems for food preservation using ammonia as the refrigerant gas. This system worked successfully in the Menier chocolate factory in Paris.

Carl Von Linde, who was able to benefit from the previous studies, produced his first compression machine in 1875 using methyl alcohol as a refrigerant gas. A year later he produced his first compression system using ammonia as the refrigerant gas. In 1877 he replaced the original vertical compressor with a horizontal double-acting compressor. A score of years later, 75 % of ice producers in the USA were using machines with the same system.

How did refrigeration spread?

Among the first domestic refrigerators was the General Electric Audiffren made using the studies of a French monk by the name of Marcel Audiffren and dating from 1911. These refrigerators used sulphur dioxide as a refrigerant gas using a hermetic compressor.

There is also another device attributed to Fred W Wolf (1913) and marketed under the Domelere brand name. The price was exorbitant, almost 1000 dollars at the time, twice the price of a Ford T. In 1918 Frigidaire and Kelvinator began industrial production by modifying the original structure and the latter company added a thermostat for temperature regulation. A monobloc structure was still a few years away, but more than a million units were already being sold despite the dangerous nature of the refrigerant gases used up to that time. The refrigerant gases used, such as methyl formate, sulphur dioxide and sulphur dioxide, were toxic, corrosive and flammable.

The great impetus for the introduction of domestic refrigerators came in 1931 when DuPont introduced CFCs, better known as “Freons”, as refrigerant gases. All the refrigerant gases used until then were, to a large extent, toxic, poisonous, with a very high explosive index. In the case of CO2, they worked at very high pressure. At the time, this contribution opened up the possibility of making domestic refrigeration systems practically risk-free, with dimensions and costs that were affordable for middle-class American families. Hence the introduction of domestic refrigeration in much of the world.

Evolution and development

As is always the case, in this case in the history of refrigeration, scientific development enabled its evolution and implementation.

In this case, the pressing factors have been the advent of the steam engine and its subsequent implementation in electric power generating systems and their distribution, especially in urban areas. But it was the advent of electricity that gave the greatest impetus to the development and implementation of mechanical compression refrigeration systems.

The first fridge appeared in Spain in 1952, I don’t know its price, but in 1962 a fridge in Spain cost 11.000 “Pesetas”, when the average salary was around 3.000 “Pesetas”.

What is happening with freons?

Freons, which have brought so much benefit to the development of refrigeration, especially commercial and domestic refrigeration, have proved to be damaging to the environment for two basic reasons:

The presence of chlorine in their formulation causes serious damage to the ozone layer and even many of the recently introduced HFCs have a high greenhouse effect due to the presence of carbon molecules.

In 1987, the Montreal Protocol for the phase-out of chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) was drawn up.

The Kyoto Protocol 1997 establishes a legally binding commitment to reduce or limit emissions. It came into force in February 2005, establishing net greenhouse gas emission reductions for the main developed countries and economies in transition, with a timetable for compliance.

Subsequently, the Paris protocol entered into force with the goal of limiting global warming to below 2 °C, preferably 1.5 °C compared to pre-industrial levels.

At the European level there is the so-called F-Gas, which, with the successive developments and proposals for legislation currently under consideration, tends to propose in practice the elimination of the use of halogenated gases in newly built appliances from 2025 onwards.

The refrigeration industry is responding to this challenge with development based on natural refrigerant gases with near zero GWP ratings. At the same time, the refrigerant gas content in refrigeration systems is being reduced.

Intarcon excels in its production with gases such as ammonia and propane (R290) with extremely high performance characteristics and low pressure operation without excluding carbon dioxide for low temperature applications.