intarCUBE

Compact refrigeration unit

Ultra-compact and soundproofed refrigeration unit for commercial refrigeration at positive or negative temperature.

- Description

- Technical features

- Options

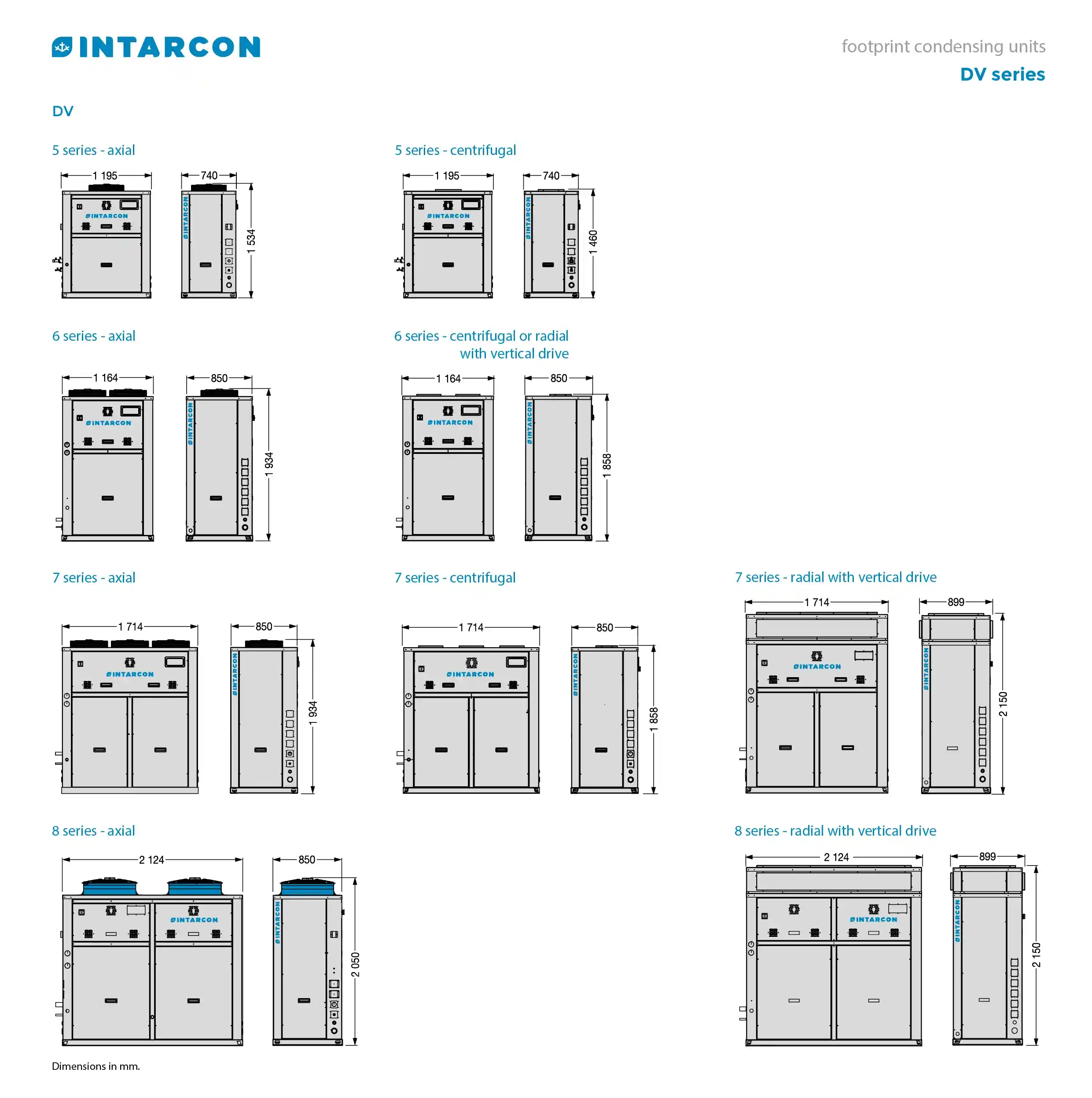

- Dimensions

- Documentation

Description

Fooprint condensing units with one to three compressors, with axial or centrifugal condensation, for medium and low temperature, with electrical panel and electronic

control (depending on version). These equipments are characterised by:

- Axial fans for outdoor installation.

- Radial fans for indoor installation in technical rooms.

- Very compact design.

- Quiet and efficient operation.

- Low investment and maintenance costs.

- Quick installation in new or existing

installations. - F-Gas 2022 and Ecodesign compliant.

Scroll or hermetic compressor.

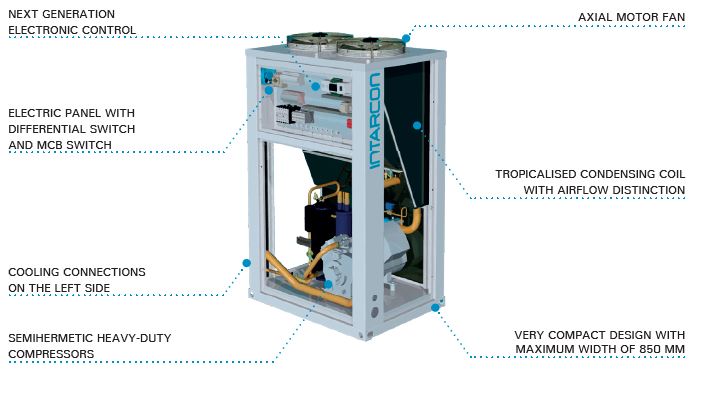

Semihermetic compressor.

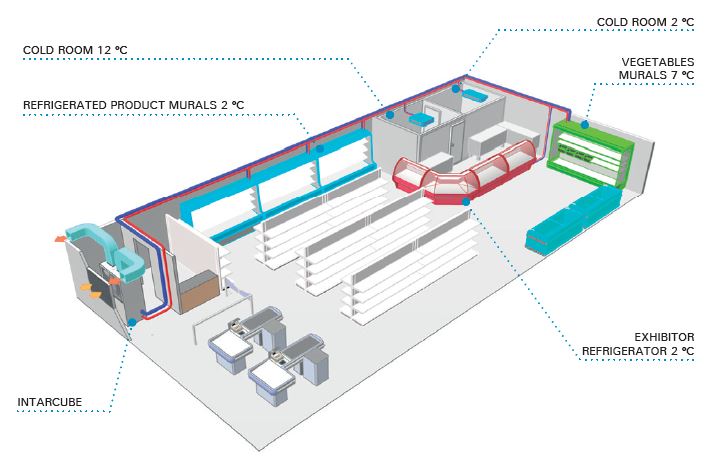

Applications

intarCUBE condensing units are designed to centralise the refrigeration production of a set of evaporator units. Also, intarCUBE footprint condensing units in centrifugal version are designed for installation in a machine room with ducted air discharge.

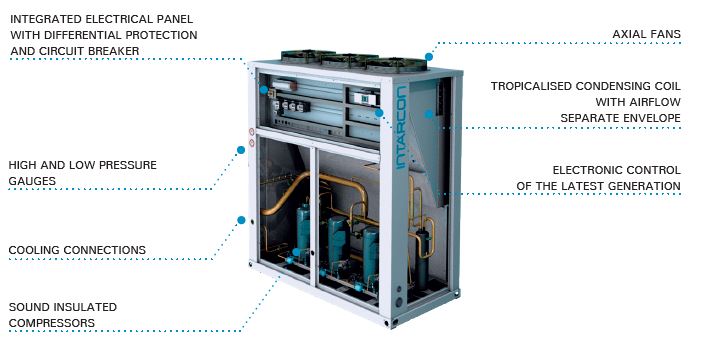

Hermetic and scroll compressors

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Hermetic alternative compressors, with discharge silencer, or scroll, in a soundproofed compartment independent of the air flow.

- Sound insulation of compressors, silentblocks, internal clixon and crankcase heater.

- Axial or centrifugal fans with variable speed.

- Refrigeration circuit equipped with high and low pressure switches, ceramic dryer filter, liquid receiver and sight gauge.

- Full control and power panel, with differential switch protection and MCB switch.

- Liquid injection system for negative temperature models.

- Fan for cooling the electrical panel.

Semihermetic compressors

- 400V 3N 50Hz power supply. Available in 60 Hz. Other voltages by request.

- Copeland Stream semihermetic compressor, with rotalock service valves, mounted on shock absorbers, crankcase heater and CoreSense™ electronic compressor diagnostic and protection module.

- Condenser coil made of copper pipes and aluminium fins.

- Variable speed fan condensation pressure control by voltage variation (6 and 7 series), and condensation pressure control by double speed (star-delta) of the axial motor fans (8 series).

- Cooling circuit equipped with oil separator, high and low pressure switches, ceramic filter, liquid receiver and sight glass.

- Electrical power and control panel, with differential protection and thermal and magneto-thermal protection of compressor/s and motor fan/s.

- Fan for cooling the electrical panel.

Hermetic and scroll compressors

- VRC system for cooling capacity modulation for hermetic compressors (V version).

- Digital Scroll system (S version).

- Oil separator (standard in tandem of two scroll compressors in low temperature, and trios in medium and low temperature).

- Anti-corrosion coil coating.

- Automatic emergency manoeuvre.

- Discharge check valve.

- Low voltage and phase change protection.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.

- Radial electronic EC fans (6 and 7 series).

Semihermetic compressor

- Anti-corrosion coil coating.

- Automatic emergency manoeuvre.

- Discharge check valve (radial version).

- Low voltage and phase change protection.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.

- Radial electronic EC fans.

- Digital compressor control (B version).