Prevent your competition from overtaking you: Improve your EBITDA with CAES

INTARCON2025-04-25T08:41:09+02:00When you are looking to improve your company’s competitiveness, it makes sense to focus on the investments that offer the greatest short-term impact: those that require little investment and generate a quick return by optimising direct costs such as raw materials, process times, waste or energy inputs.

However, there are larger strategic investments that, despite their significant impact on the profit and loss account, are often postponed for reasons such as:

- High initial investment.

- Technical complexity.

- Regulatory or political uncertainty.

- Financing costs.

- Competition with other investments of similar profitability.

What are CAES and why can they make a difference?

Certificates of Energy Saving (CAES) are revolutionising this landscape. They allow monetisation of investments aimed at reducing energy consumption, altering the traditional payback time equation. How? They offer income from the moment the investment is made, even with payback options.

CAES have a direct and positive impact on the bottom line:

- Energy cost reduction: Immediate gross margin improvement.

- Revenue generation: A positive cash flow associated with the investment.

- Improved EBITDA: Increased operating profitability.

- Carbon footprint reduction: More sustainable positioning.

- Additional optimisation: Better equipment, lower maintenance and higher reliability.

When we combine thermal imagination with financial intelligence, the possibilities are enormous. Industries with high energy demand can transform their business, reducing vulnerabilities to unforeseen scenarios affecting the cost of electricity or gas.

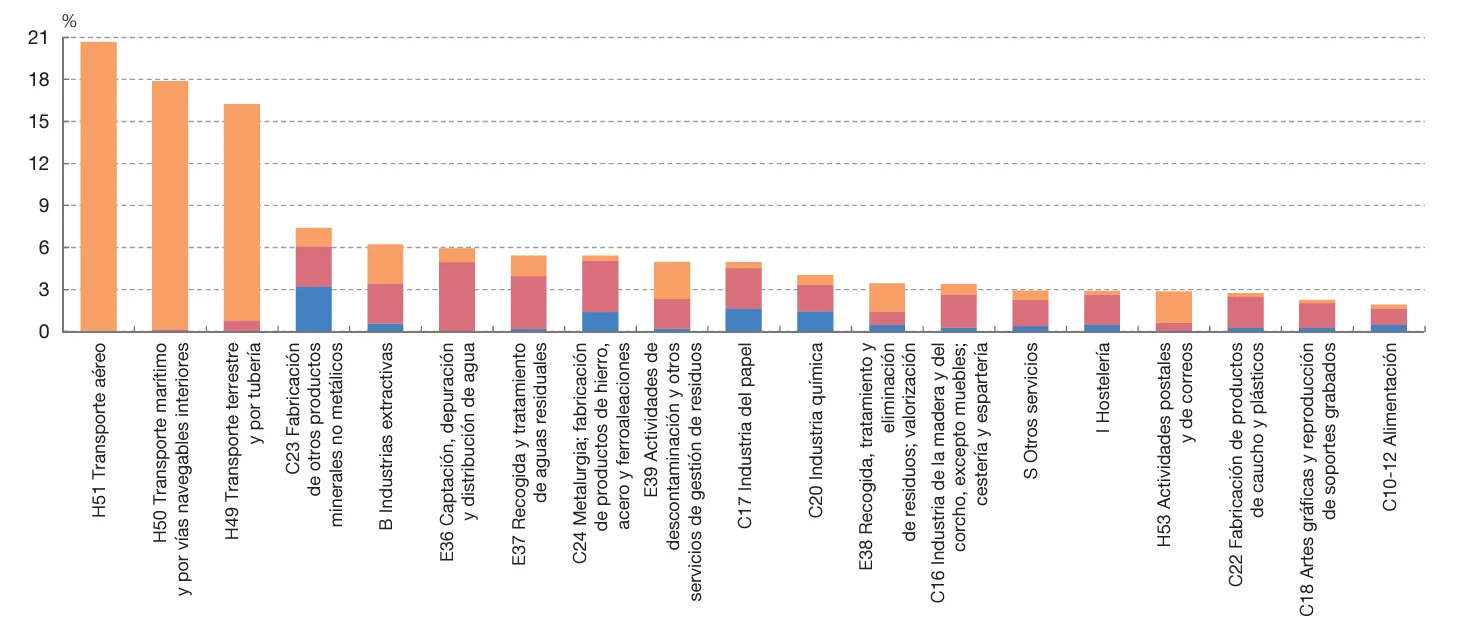

In the graph below, we analyse the impact of energy costs on turnover in different sectors:

THE ENERGY SPENDING OF SPANISH INDUSTRIAL AND SERVICE COMPANIES [María de los Llanos Matea and Alejandro Muñoz-Julve] [María de los Llanos Matea and Alejandro Muñoz-Julve].

What is stopping you from acting now?

Your competitors are probably already exploring these opportunities. Don’t miss out on the competitive advantage that CAES can offer. To show you the potential, here are some extended practical examples:

Hotel undergoing refurbishment

The hotel sector offers multiple fronts to optimise energy consumption and improve profitability. Some key areas:

- Efficient air conditioning: Replacing old equipment with modern systems such as geothermal or aerothermal heat pumps. Intelligent zoning to avoid unnecessary cooling or heating of spaces.

- Optimisation of the thermal envelope: Improving insulation in walls, roofs and windows to reduce energy losses. Use of reflective materials to mitigate heat gain in hot climates.

- DHW (Domestic Hot Water) production: Solar thermal systems to complement DHW production. Heat recovery from cooling systems to pre-heat water.

- Intelligent monitoring and control: Sensors and IoT systems to manage consumption in real time. Systems that automatically adjust consumption according to hotel occupancy.

Additional impact: These measures not only reduce energy costs, but also improve customer perception of sustainability and quality, generating added value for the brand.

Water treatment plant

Water treatment plants consume a large amount of energy, especially in the pumping and aeration processes. Specific solutions:

- High efficiency pumps: Replace traditional pumps with models with latest generation motors, such as IE4 or IE5 motors. Incorporate frequency variators to adjust consumption to actual demand.

- More efficient aeration systems: Fine bubble diffusers that increase oxygen transfer with lower energy consumption. Continuous monitoring of dissolved oxygen levels to optimise aeration cycles.

- Energy recovery: Systems to utilise biogas generated in anaerobic digestion processes. Heat recovery from treated water to pre-heat internal systems.

Additional impact: These improvements not only lower operating costs, but also enable compliance with stricter environmental regulations and improve the sustainability of the process.

Food freezing industry

Frozen food consumption is booming, even more so in developed countries. The growth of restaurants, tourism and changes in society’s behaviour are leading to an increasing percentage of the shopping basket being made up of cooked or frozen products. Here are some key lines for this type of industry:

- Energy recovery in thermal processes: Recover waste heat from cooling processes and use it in preheating or defrosting processes. Waste heat recovery for use in defrosting systems.

- Insulation improvements: Use of high performance materials in cold rooms and freezing tunnels. Minimising thermal leakage with high-speed doors and double-locking systems.

- More efficient refrigeration equipment: Replace traditional compressors with variable speed drive systems. Implement systems with natural refrigerants (CO2 or NH3) that are more efficient and sustainable.

- Optimisation of process times: Automation of production lines to reduce freezing and cooling times.

Additional impact: Energy savings directly reduce production costs, while the reliability and modernisation of equipment ensures less downtime and less waste.

Industrial furnaces and heaters

In this type of industry, energy can represent values above 10% of its turnover, while natural gas is the main source. Hybridising these boilers with renewable sources (heat pumps), implementing heat recovery systems and envelope improvements can reduce this consumption to less than half. Some key solutions:

- Hybridisation with industrial heat pumps: supplementing furnaces with high-temperature heat pumps for material pre-treatment or pre-heating.

- Heat recovery systems: Recover heat from flue gases and reuse it in internal processes. Incorporate heat exchangers to maximise efficiency.

- Optimisation of boilers and enclosures: Improvements in the thermal insulation of furnaces to reduce losses.

- Digitisation of thermal control: Advanced sensors to adjust temperature in real time according to process load.

Additional impact: These measures not only reduce energy consumption, but also increase production capacity, which improves the overall performance of the facility

Conclusion

CAES offer a unique opportunity to transform your business, combining operational efficiency, sustainability and profitability. The solutions described are not only technically feasible, but also within reach with the right financial backing.

Prepared by: Manuel García Jiménez