intarWatt

Large capacity refrigeration plants

Large capacity and compact industrial plants, with semi-hermetic compressors, V-shape condensing coils and in-built control board.

- Description

- Technical features

- Options

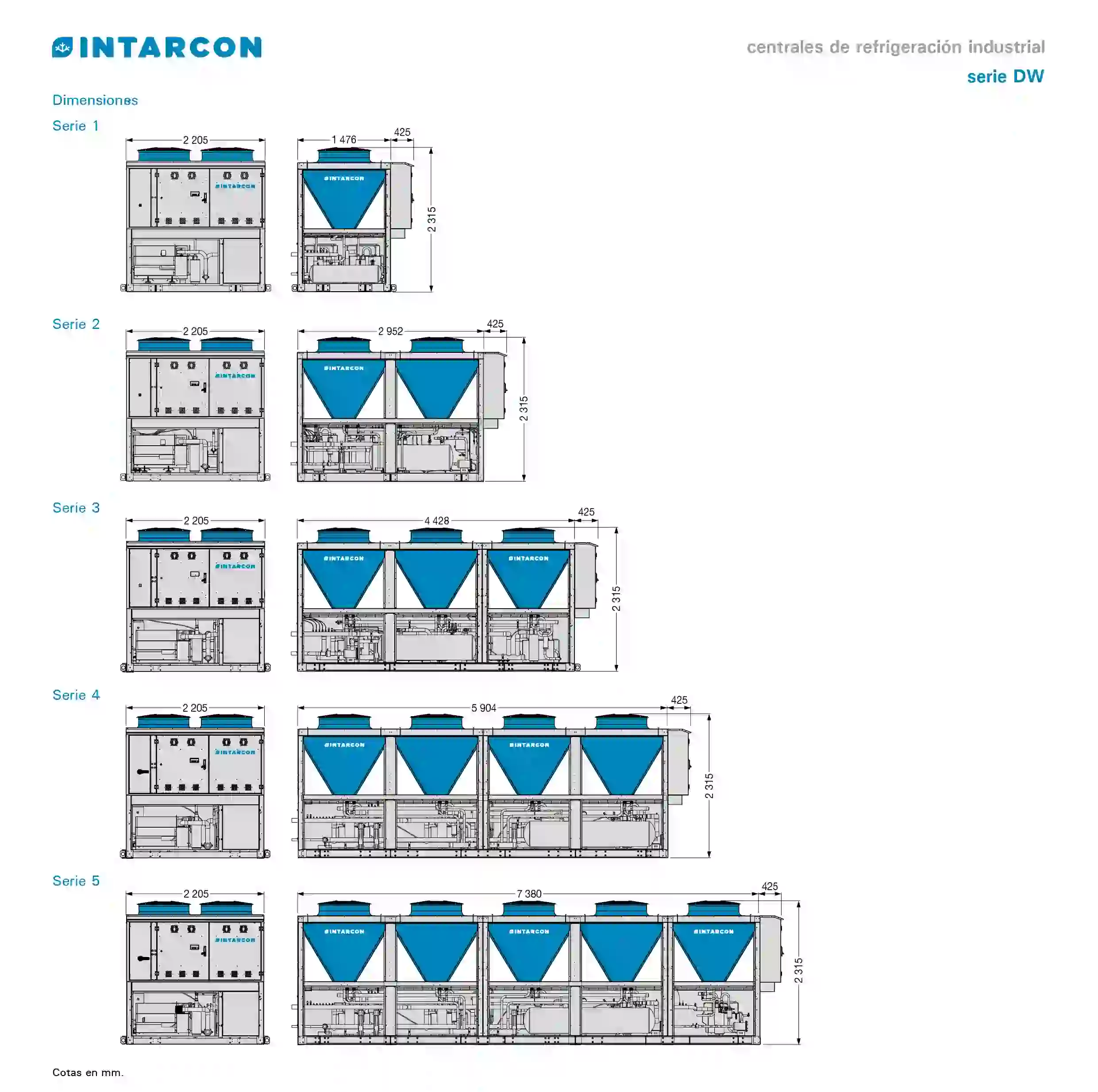

- Dimensions

- Documentation

Description

The intarWatt range consists of high-power air-cooled condensing unit for industrial applications. These equipments are characterised by a very compact construction designed for outdoor use, which integrates the semihermetic compressor set, air condensers with V-coil arrangement, and the control and power panel.

- Low refrigerant charge.

- Large cooling capacity.

- Semihermetic compressors.

- Great service accessibility.

Configurations:

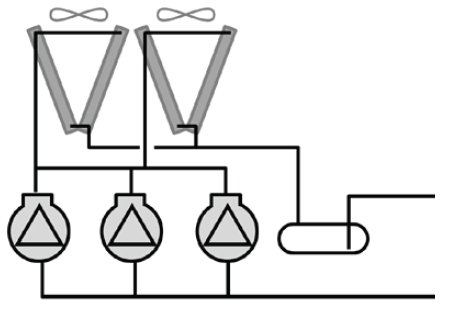

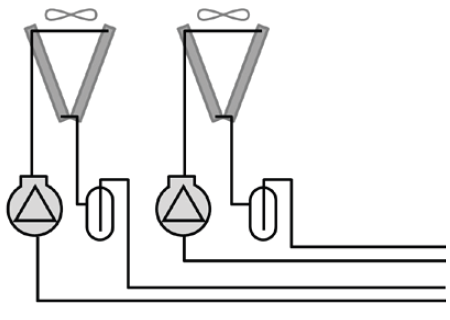

- DX condensing units configuration: Cooling circuit with parallel compressor rack and common condensation. With oil separators per compressor, common oil accumulator and level controls and electronic oil injectors for each compressor.

- Multi-circuit configuration: Multiple refrigeration circuits, each consisting of one or two compressors and a V-shaped air condenser module with two motor fans. Each circuit incorporates oil separators and balancing lines.

- 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- Semihermetic compressors Copeland Stream, mounted on shock absorbers and acoustically insulated with capacity modulation, rotalock service valves, crankcase heater and electronic CoreSense module protection and diagnostics.

- High-efficiency V condensing coils, made of copper pipes and aluminium fins, Ø 800 mm axial fan motors with double speed.

- Cooling circuits manufactured in annealed copper tube equipped with high and low pressure switches, service valves, safety valves, liquid receiver, filter and sight gauge.

- Oil separators and balance lines 1 and 2 compressor condensing units , oil accumulator with individual electronic fuel injection for each compressor in unit of 3 compressor.

- Electrical panel with overload and differential protection for each compressor and fan.

- Electronic control with high and low pressure transducer, and suction temperature sensor, compressor discharge, liquid line, and ambient temperature; suction pressure control and condensing pressure control; management and recording of alarms; mountable remote digital display; and integration of CoreSense protections.

- Manual emergency manoeuvre by means of a pressure switch for compressor and fan management, with automatic activation.

- One compressor with digital capacity control (B version).

- Microchannel aluminium coils.

- Variable speed electronic axial fan.

- Hot gas defrost.

- Anti-corrosion coil coating.

- Low voltage and phase change protection.

- Heat recovery (20 or 80 % condenser heat) for hot water generation.

- Interior fairing of frigorific compartment.

- Suction separator.

- Suction filter.