ECO2Watt

CO2 plant with double suction line

CO2 plant with the double suction line, air-cooled, to obtain a total cooling capacity of 50 to 300 kW (PT + NT).

- Description

- Technical features

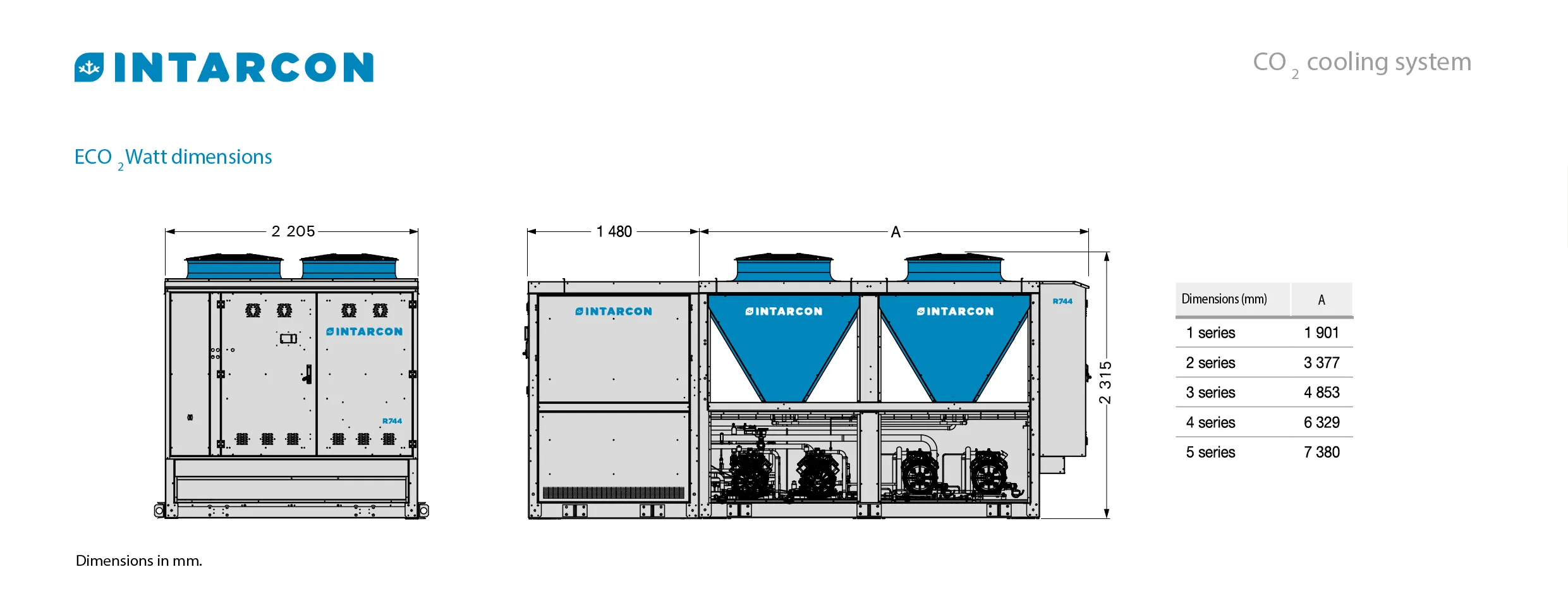

- Dimensions

- Documentation

Description

ECO2Watt are great cooling capacity CO2 condensing units, single or double suction transcritical cycle with built-in gas cooler, or in cascade cycle, designed according to the needs of the installation for a total cooling capacity between 80 and 300 kW. These equipment are characterised by:

- Large maintenance access.

- No engine room.

- Custom design.

- Construction in galvanised sheet steel structure with epoxy paint.

- Sets of CO2 compressors equipped with rotalock valves.

- Inverter capacity control per compressor group.

- Particulate separator and CO2 filter.

- Oil separator and accumulator with oil filter and electronic compressor injection.

- Medium pressure CO2 receiver (PS: 60 bar) with double safety valve.

- Economiser – liquid CO2 subcooler.

- Instrumentation panel with pressure gauges and load taps.

- Integrated control and power panel with electronic control unit for compressor and

electronic valve management. - Emergency unit for CO2 maintenance.

Transcritical ECO2Watt

- Set of transcritical CO2 compressors and set of compressors in parallel. Inverter drive in one compressor of each set.

- Double pressure control valve.

- Pressure regulating valve with medium pressure relief.

- Internal economiser exchanger.

- Gas cooler with copper tube coils and aluminium fins in parallel.

- PS: 120 bar. Variable speed EC axial motor fans.

Cascade ECO2Watt

- Up to triple cascade plate heat exchanger with gravity circulation.

- High temperature refrigerant R-290 or HFC.

- Semihermetic high temperature compressors, with Inverter drive in one compressor.

- High temperature circuit made of copper, with filter, sight glass and electronic expansion valves.

- Copper tube and aluminium finned coil condenser in parallel V configuration.

- Variable speed EC axial motor fans.