Water pump sets

Pump sets

For consumption water

- Description

- Technical features

- Applications

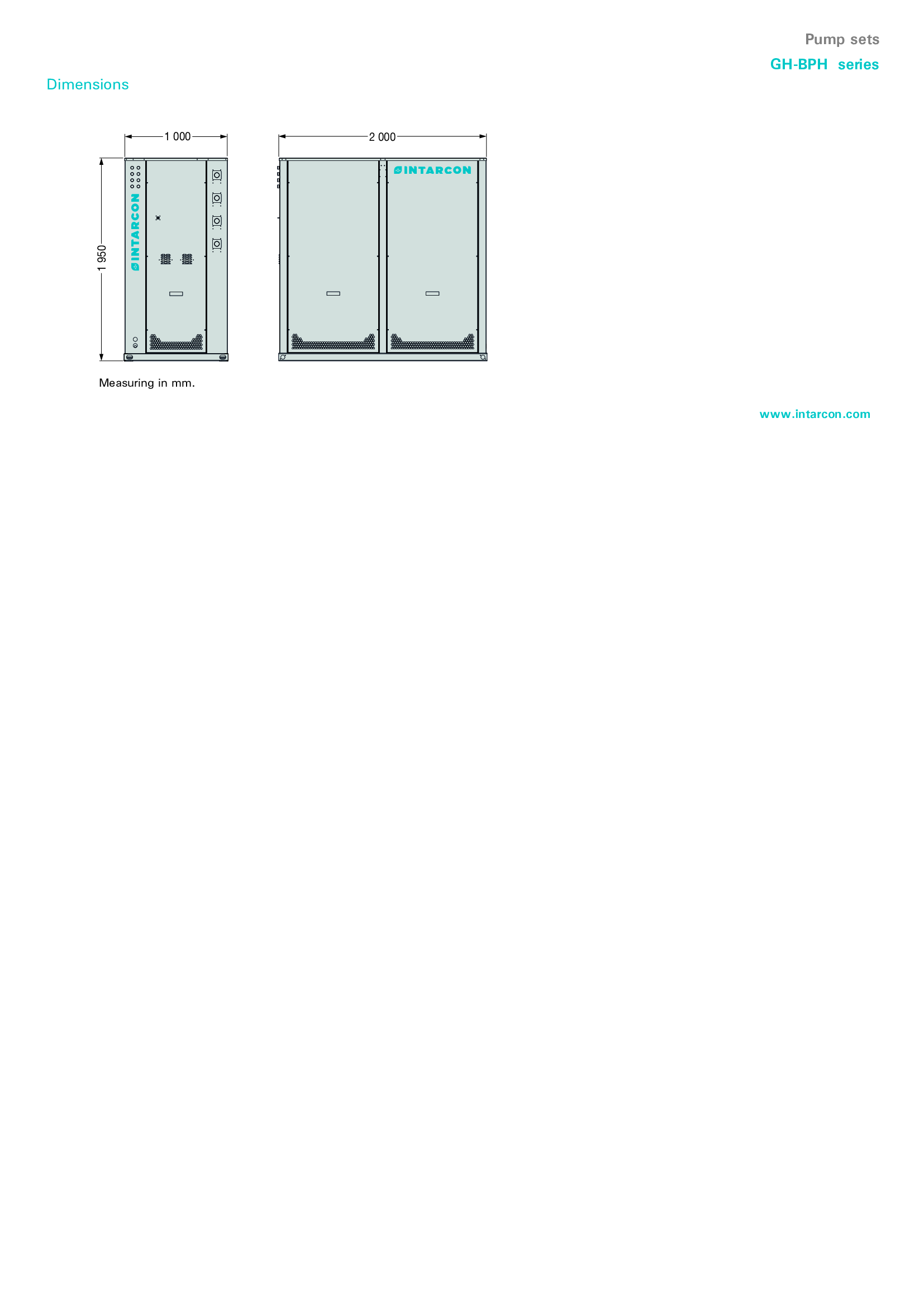

- Dimensions

- Documentation

Description

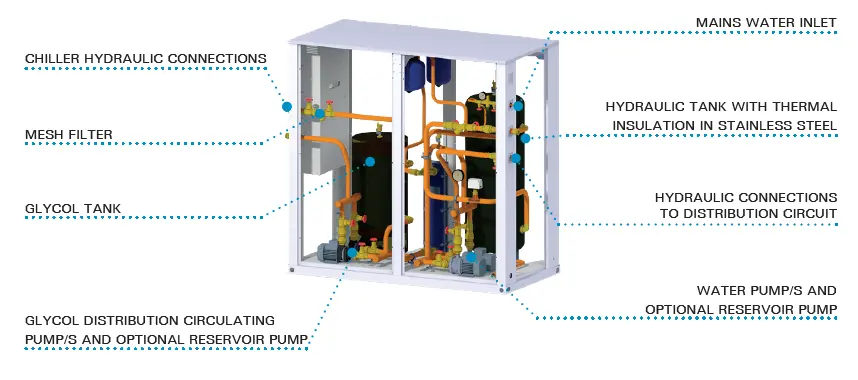

Hydraulic unit for cooling mains water in closed circuit, assembled in galvanised sheet steel bodywork and structure with polyester paint and copper piping, for outdoor installation. Prepared

to supply water at 2 °C to a recirculation and consumption ring. Our water pump sets stand out for:

- Easily integrated modular construction.

- Optimised water and glycol assemblies.

- Compatible with Sigilus (WF) and intarcube (WV) chillers.

B version.

– GV-BH-2: Secondary circuit pump set.

- 400V 3N 50Hz power supply. Available in 60Hz. Others voltages by request

- Glycol circulating pump+ Glycol circuit reserve pump.

- Consumption water circulating pump+reserve pump built in AISI-304 stainless steel.

- Glycol circuit buffer tank with high density polyurethane foam insulation and vapour barrier.

- Water circuit AISI-304 stainless steel buffer tank with high density polyurethane foam insulation and vapour barrier.

- Heat exchanger with removable AISI-304 stainless steel plates and gaskets.

- Closed diaphragm expansion vessel and ducted safety valve for each circuit.

- Mesh filter.

- Glycerine thermometers and pressure gauges, air vent and drain connection.

- Continuous water recirculation to minimise consumption.

- Check valves at mains water inlet and water return.

- Threaded hydraulic connections.

- Electrical control and power panel with magneto-thermal protection and independent differential for each pump, and electronic control unit for management and rotation of

primary and secondary circuit pumps. Communication with chiller plant for set-point management. Set-point management. - Adjustable cold water outlet temperature between +15 °C and +1 °C.

Food production

In order to control temperatures during the food production process to prevent the growth of micro-organisms, or to perform a thermal shock by mixing it with refrigerated water, the following food process steps stand out:

- Dilution of concentrates in the production of beverages (juices and soft drinks)

and production of sauces and dressing. - Mixing of dry ingredients and temperature control in baking.

- Mixing of dry ingredients with water to maintain proper temperature and adjust consistency in the production of ice cream, sorbets and pastries.

- Pharmaceutical products preparation.

- Cooling of perishable products such as soups and broths.

- Charcuterie industry to avoid temperature increase during the mixing process of ingredients.

- Seafood processing for refrigeration, defrost, cooking or temperature holding.

Fruit and vegetables washing and pre-cooling

Temperature is the most relevant factor affecting the deterioration of harvested fresh product, directly affecting its respiration rate and the release of ethylene that induces ripening. Temperature lowering is the most efficient post-harvest technique to maintain the quality of fruit and vegetables and to extend their sales period.

Water pre-cooling for ice production

In order to increase efficiency, decrease production time and increase the capacity of ice making equipment, supplying water at a temperature as close to freezing point as possible increases the performance of new or existing equipment.

Dimmensions in mm.