intarbox

Axial and centrifugal motocondensing units

Axial and centrifugal motocondensing units for positive or low temperature refrigeration

- Description

- Technical features

- Options

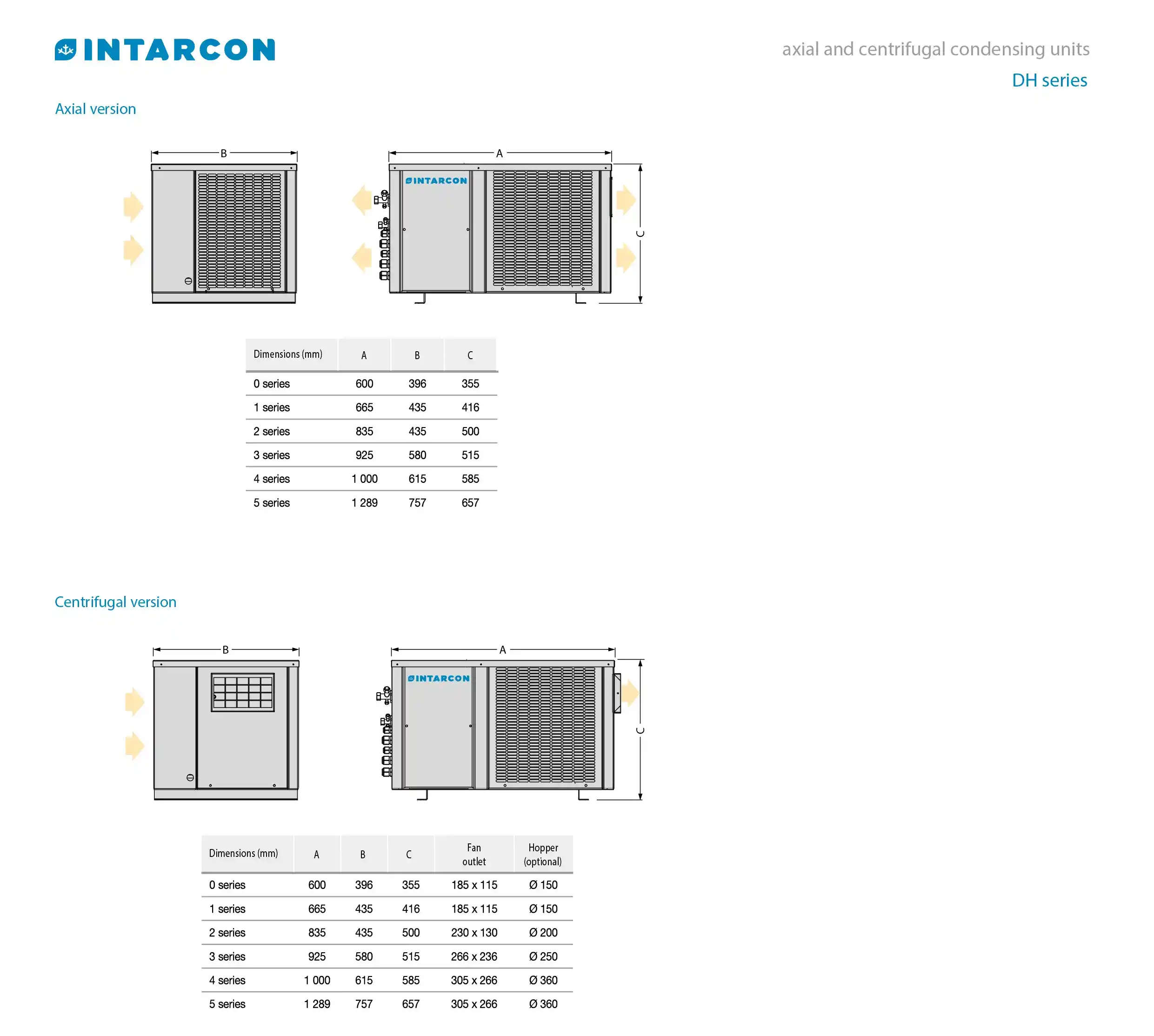

- Dimensions

- Documentation

Description

Air-cooled packaged condensing units at positive or negative temperature, in horizontal construction with an alternative hermetic or scroll compressor, and low speed axial or centrifugal motor fan. The motocondensing unit intarbox is characterised by:

- Designed for ambient temperature up to 45 ºC.

- Multi-service version with VRC cooling capacity modulation system.

- Liquid injection system for compressor refrigeration.

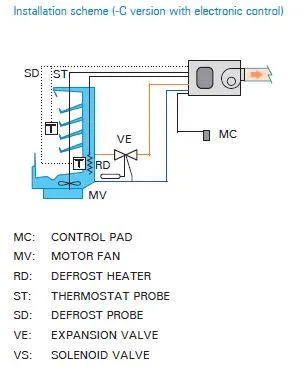

Installation scheme (-C version with electronic control)

Versions

- -N version: Without electrical board. Designed for on/off operation depending on the suction pressure (pump-down). With electrical board as an option. Electronic controller to manage the condensing unit and the evaporator built-in solenoid valve as an option.

- -V version (multi-service): The multi-service version features VRC system to adjust the refrigerant flow to the demand of the evaporators, keeping the pressure constant in suction the line. The VRC system is composed of a set of pressure and temperature control valves to progressively modulate cooling capacity from 100 % to 10 % of its nominal capacity, while reducing energy consumption and preventing compressor overheating.

- -S version (scroll):Version designed with scroll compressors.

- 230V 50Hz or 400V 3N 50Hz power supply. Available in 60 Hz. Others voltages by request.

- R-134a or R-449A refrigerant, other refrigerants by request.

- Hermetic reciprocating compressor mounted on shock absorbers, with discharge muffler and internal klixon.

- High performance condensing coil in copper pipes and aluminium fins.

- Centrifugal motor fan with available static pressure for a ducted outlet of condenser hot air (centrifugal version).

- Refrigeration circuit equipped with HP and LP switches, filter dryer, liquid receiver and sight gauge.

- Digital control of condensation pressure with the optional electrical board, and all-nothing condensation control with condensers without electrical panel.

- Proportional control of condensing pressure through fan speed variation (included in MDH series 4).

- Full control and power board with compressor and motor fan protection.

- Liquid injection system for negative temperature models with R-449A.

- Change to 400 V-III-50 Hz power supply.

- Proportional control of condensing pressure through speed variation (axial 3 series and centrifugal 0 up to 3 series).

- Built-in oil separator (already included in -V version).

- Crankase heater.

- Built-in solenoid valve with body and coil (except for -V version).

- Anti-corrosion coil coating.

- Non-return damper (centrifugal version).

- Adaptation of air discharge to circular duct.

- Vertical discharge (centrifugal version).

- Control and power panel with electronic control unit for management of condenser and evaporator.

- Larger sized multifunction electronic control.