Hot

NH3 ammolite chiller

Chillers plants

NH3 chillers

- Description

- Technical features

- Options

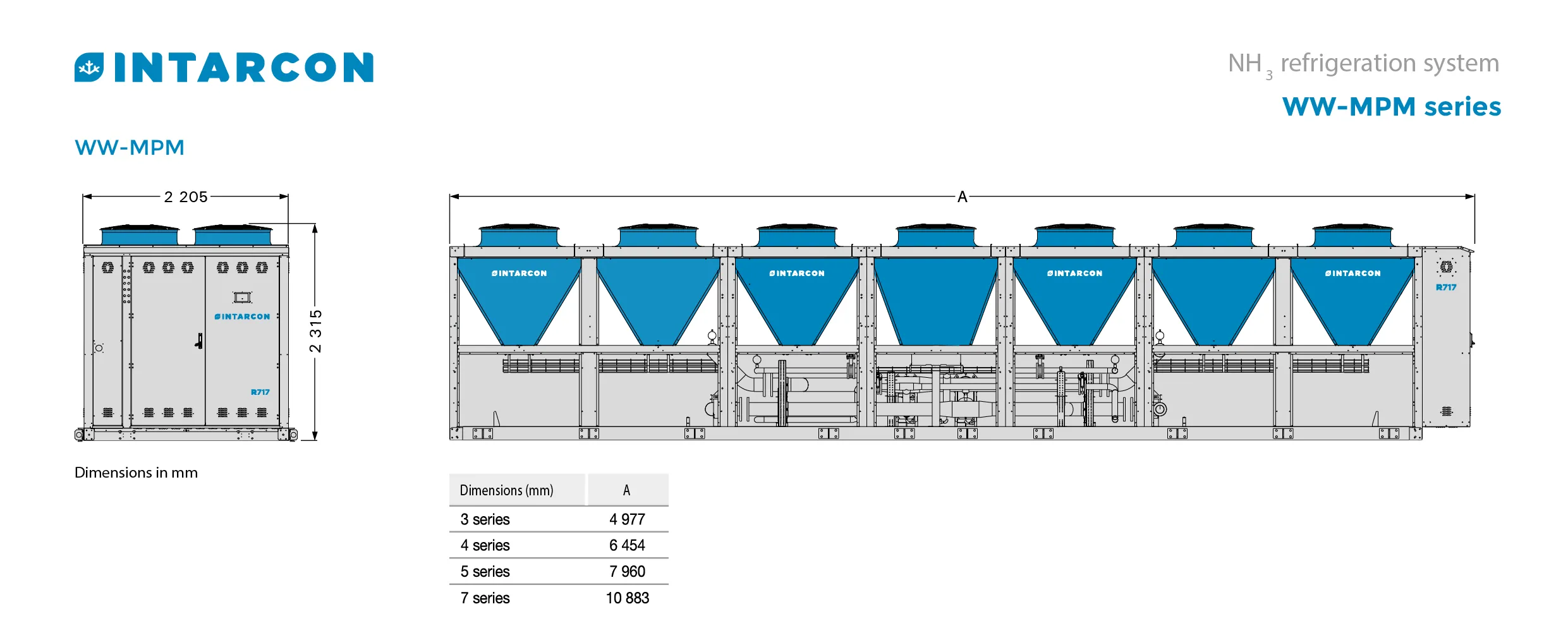

- Dimensions

- Documentation

Description

- 400V 3N 50Hz power supply. Available in 60 Hz. Other voltages on request.

- Semihermetic screw compressors with variable speed permanent magnet motor.

- Suction filter, oil filter, discharge check valve. Suction and discharge valves integrated in the compressor.

- Miscible oil.

- High efficiency vertical oil separator.

- Tropicalised condenser with aluminium microchannel coils, with Polyester Powder Coating treatment.

- Oil cooler with stainless steel tube coils and aluminium fins.

- Variable speed EC motor fans for condensing pressure and oil temperature control.

- Evaporator with stainless steel welded plates with stainless steel welding.

- Electronic expansion valve, and electronic liquid injection valve for compressor cooling in extreme conditions.

- Stainless steel refrigeration circuit per compressor with decanter. Filter service valves, sight glasses, pressure switches and high and low pressure transducers.

- Stainless steel hydraulic circuit with fill/drain valve, air vent, flow switch, inlet and outlet thermometers and pressure gauges.

- Closed economiser with plate heat exchanger for liquid subcooling and medium pressure injection (only in negative temperature models).

- Electrical control panel. Frequency variator per compressor. Differential protection.

- Individual magneto-thermal and thermal protection for compressor and fans.

- Electronic control with digital control panel, cooling capacity control, condensation control, VI variation, start/stop sequence, compressor, fan and pump safety and stop sequence, compressor/s, fans and pumps safeties. Web interface and external communication.

- Multi-tube stainless steel tube evaporator.

- Stainless steel tube condenser and aluminium fins with polyurethane.

- Epoxy oil cooler coil coating.

- Variable glycol flow rate.

- Condensation heat recovery.

- Total heat recovery (80 %).

- Hydraulic unit with back-up pump